CSA/UL versions

For

UL

designed machines, calculations for

cable sections and fuses

are done according to

UL508A (Industrial control panels).

For

CSA

, calculations for

cable sections and fuses

are done according to CSA 22.2 (Canadian

electrical code).

Standard conditions:

maximum 3 copper conductors in raceway or cable with 85-90˚C (185-194

˚F) insulation at ambient temperature 30 ˚C (86 ˚F), operating at nominal voltage; cables not

grouped with other cables.

Worst case conditions:

ambient temperature > 30 ˚C (86 ˚F), maximum 3 copper conductors in

raceway or cable with 85-90 ˚C (185-194 ˚F) insulation at 46 ˚C (115 ˚F) ambient temperature

and operating at nominal voltage. Cables not grouped with other cables.

Fuse size is the maximum fuse size in order to protect the motor against short circuit. For CSA

fuse HRC form II, for UL fuse class RK5.

If the local conditions are more severe then the described standard conditions, the cables and

fuses for worst case conditions should be used.

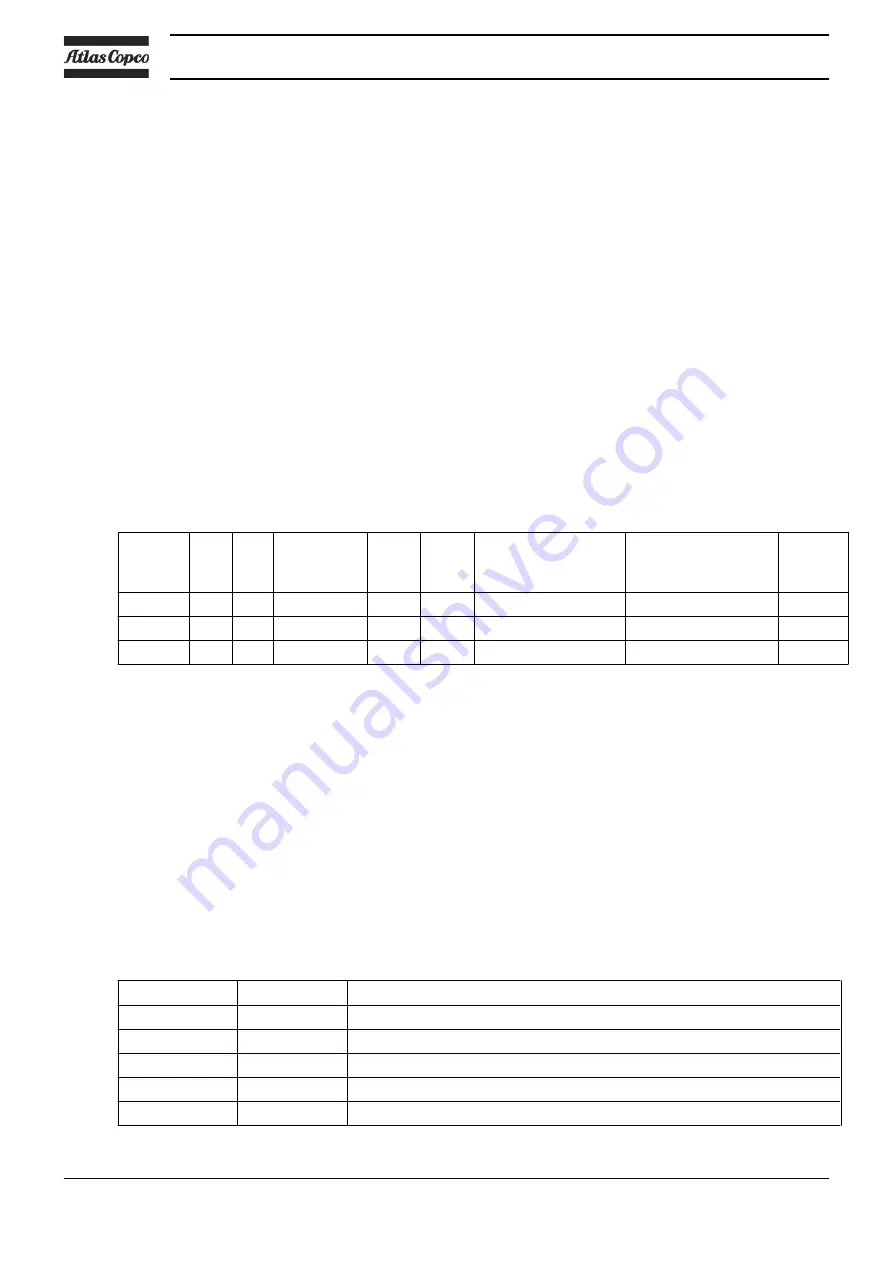

Recommended cable size

Type

V

Hz

Approval

I

tot

P

(1)

I

tot

FF

(1)

Recommended wire

section (2)

Recommended wire

section (3)

Main

fuses

(A) (4)

GA 18

200

60

CSA/UL

84

89

4 x AWG2

4 x AWG1

125

GA 18

230

60

CSA/UL

72

77

4 x AWG3

4 x AWG2

100

GA 18

460

60

CSA/UL

36

41

4 x AWG6

4 x AWG4

50

Remarks :

(1): current in the supply lines at maximum load

(2): suggested wire section under standard conditions (Pack)

(3): suggested wire section under worst case conditions (Full-Feature)

(4): Maximum fuse value - value between ( ) valid in case of 6 fuses for parallel supply cables

Fuse specifications CSA: HRC Form II - UL: Class 5

9.3

Motor overload relay settings

Overload relay settings

GA 18

Frequency (Hz) Voltage (V)

Overload relay F21 (A)

CSA/UL

Star-delta

60

200

53

60

230

46

60

460

23

Instruction book

84

API451763