25

2920 1190 05

Instruction book

Industrial Air Division

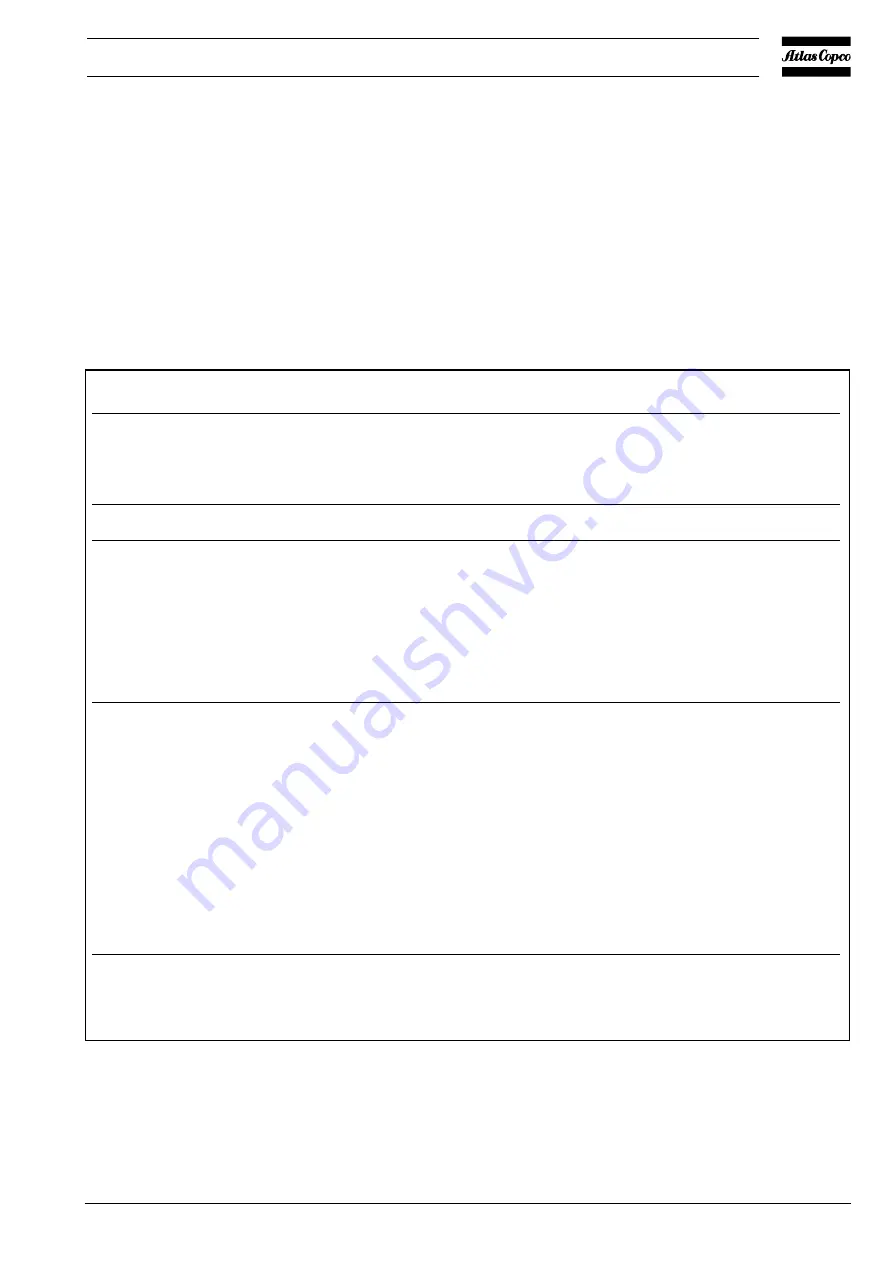

4.1 Preventive maintenance schedule for the compressor 1)

Attention:

For overhauling or carrying out preventive maintenance, service kits are available. See section 4.9.

Atlas Copco also offers several types of Service contracts, relieving you of all preventive maintenance work. For more details,

consult your nearest Atlas Copco representative.

The schedule comprises a summary of the maintenance instructions. Read the respective section before taking maintenance

measures.

When servicing, replace all disengaged packings, e.g. gaskets, O-rings, washers.

The "longer interval" checks must also include the "shorter interval" checks.

1) Use only authorized parts. Any damage or malfunction caused by the use of unauthorized parts is not covered by

Warranty or Product Liability.

2) Whichever interval comes first. The local Sales Company may overrule the maintenance schedule, especially the service

intervals, depending on the environmental and working conditions of the compressor.

Period 2)

Running

See

See

Service

Operation

hours 2)

section

note

Kit

Daily

--

3.2/3.4

--

Check oil level

"

8

3.4/7.1

--

Check readings on display

"

8

--

10

Check that condensate is discharged during operation (Da)

"

--

3.5

10

Drain condensate (Dm)

Monthly

--

--

--

Clean compressor

3-monthly --

5.3

--

Operate safety valve (SV)

"

--

--

8

Carry out a LED/display test

"

--

--

--

Check for oil leaks

"

500

--

1

Clean cooling air openings of electric cabinet

"

500

5.2

1

Inspect coolers (Ca/Co); clean if necessary

"

500

--

1/7

Remove air filter element (AF), inspect

"

500

--

4

Check pressure difference over Atlas Copco prefilters or

afterfilters (optional)

Yearly

--

5.3

--

Test safety valve (SV)

"

--

--

--

Have operation of electrical components tested

"

--

--

9

Test temperature shut-down protection

"

1,000

4.4/4.5/4.6

2/6

If mineral oil is used, change oil and oil filter (OF)

"

1,000

--

--

If mineral oil is used, inspect restrictor (Rf2) for cleanness

"

2,000

5.1

6

X

Replace air filter element (AF)

"

2,000

--

--

X

Remove, dismantle and clean float valve of moisture trap (MT)

"

2,000

--

--

If Roto-injectfluid is used, inspect restrictor (Rf2) for cleanness

"

2,000

4.6

2/6

X

If Roto-injectfluid is used, replace oil filters (OF)

"

2,000 or

4.4/4.5

3/5/6

X

If Roto-injectfluid is used, change oil

4,000

--

4,000

4.2

--

X

On GA50 VSD, regrease compressor motor bearings (M1)

--

6,000

4.7

6

X

Replace oil separator (OS)

3-yearly

1,800,000 m³ 4.2

--

X

On GA90 (W) VSD 10 bar, regrease compressor motor

bearings (M1)

"

1,300,000 m³ 4.2

--

X

On GA90 (W) VSD 13 bar, regrease compressor motor

bearings (M1)