2920 1190 05

28

Industrial Air Division

Instruction book

4.6 Oil filter change (Figs. 12)

1. Close the air outlet valve (AV-Fig. 1) and let the compressor

run at minimum speed for 3 minutes. Stop the compressor,

switch off isolator switch (S0-Figs. 1 and 3a) and open

manual drain valve (Dm-Fig. 5). Wait until the

compressor has depressurized. Unscrew oil filler plug

(FC) only one turn to permit any pressure in the system

to escape.

2. Remove vent plug (VP-Figs. 3a and 4), wait 5 minutes,

remove the drain plug in the oil filter housing and catch the

oil in a receptacle.

3. Remove oil filter(s) (OF-Figs. 9b and 12a).

4. Clean the filter seat(s) on the manifold. Oil the gaskets of

the new elements. Screw the elements into place and tighten

them firmly by hand.

5. Fill the receiver (AR) with oil until the level reaches the

filler neck (adapter part included).

6. Tighten plug (FC). Tighten the plug in the oil filter housing

and vent plug (VP-Figs. 3a and 4).

7. Reset the oil filter service warning. 1)

4.7 Oil separator change

1. Stop the compressor, switch off the isolator switch, close

the air outlet valve (AV-Fig. 1) and open manual drain

valve (Dm-Fig. 5). Wait until the compressor has

depressurized. Unscrew oil filler plug (FC-Figs. 12) only

one turn to permit any pressure in the system to escape.

2. Disconnect the flexibles from the minimum pressure valve

(Vp-Fig. 12a) and air receiver cover.

1) Consult the "User manual for Elektronikon regulator", section

"Service submenu".

Example

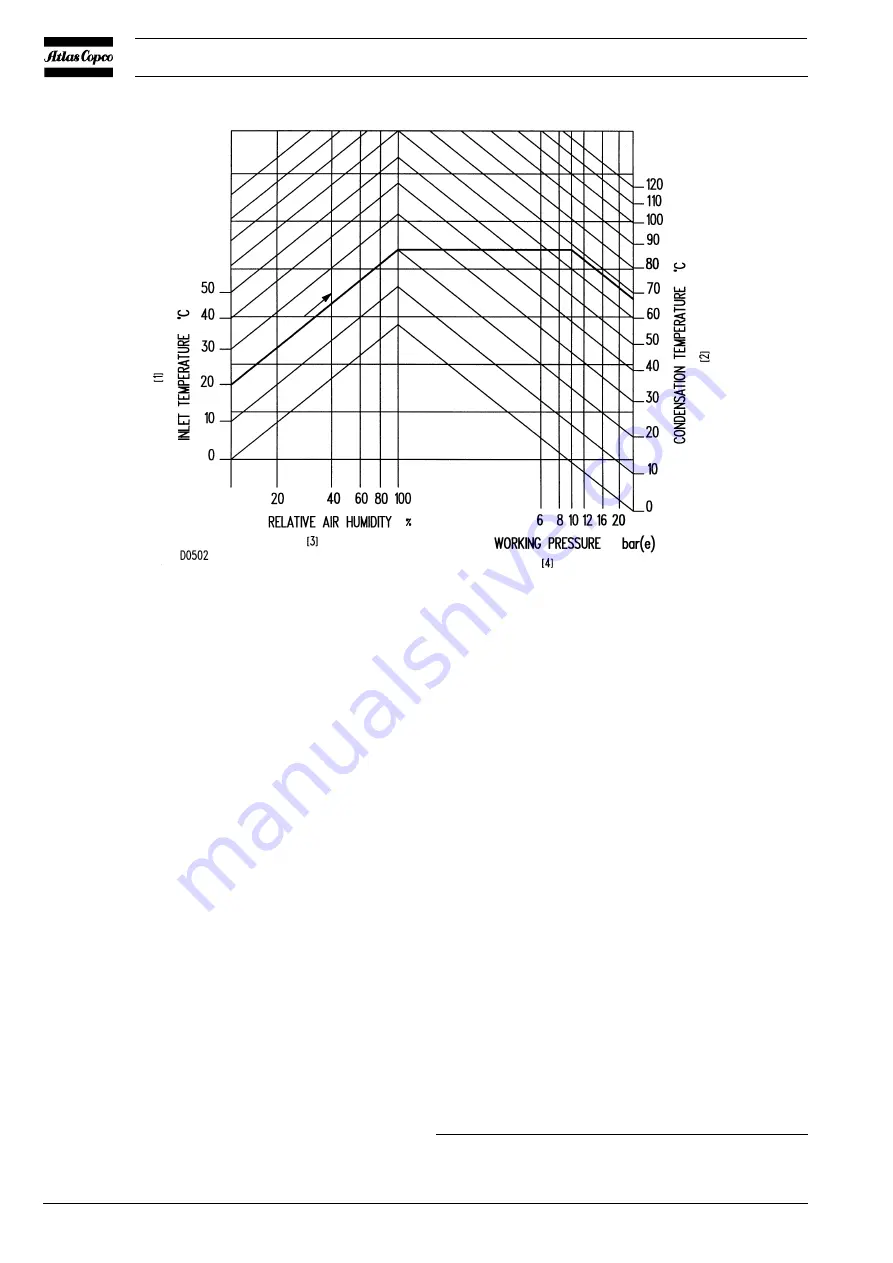

If operating at a pressure of 10 bar(e) in an ambient temperature of 20°C and at a relative air humidity of 100 %, the minimum

temperature to prevent condensate from forming is 68°C. Regulate the cooling water flow during loaded operation to obtain a

temperature between 70°C and approx. 75°C at the outlet of the compressor element.

Fig. 15. Minimum allowable air temperature at outlet of compressor element (water-cooled compressors only)