30

2920 7090 00

Instruction book

9820 4496 00/01

81458D

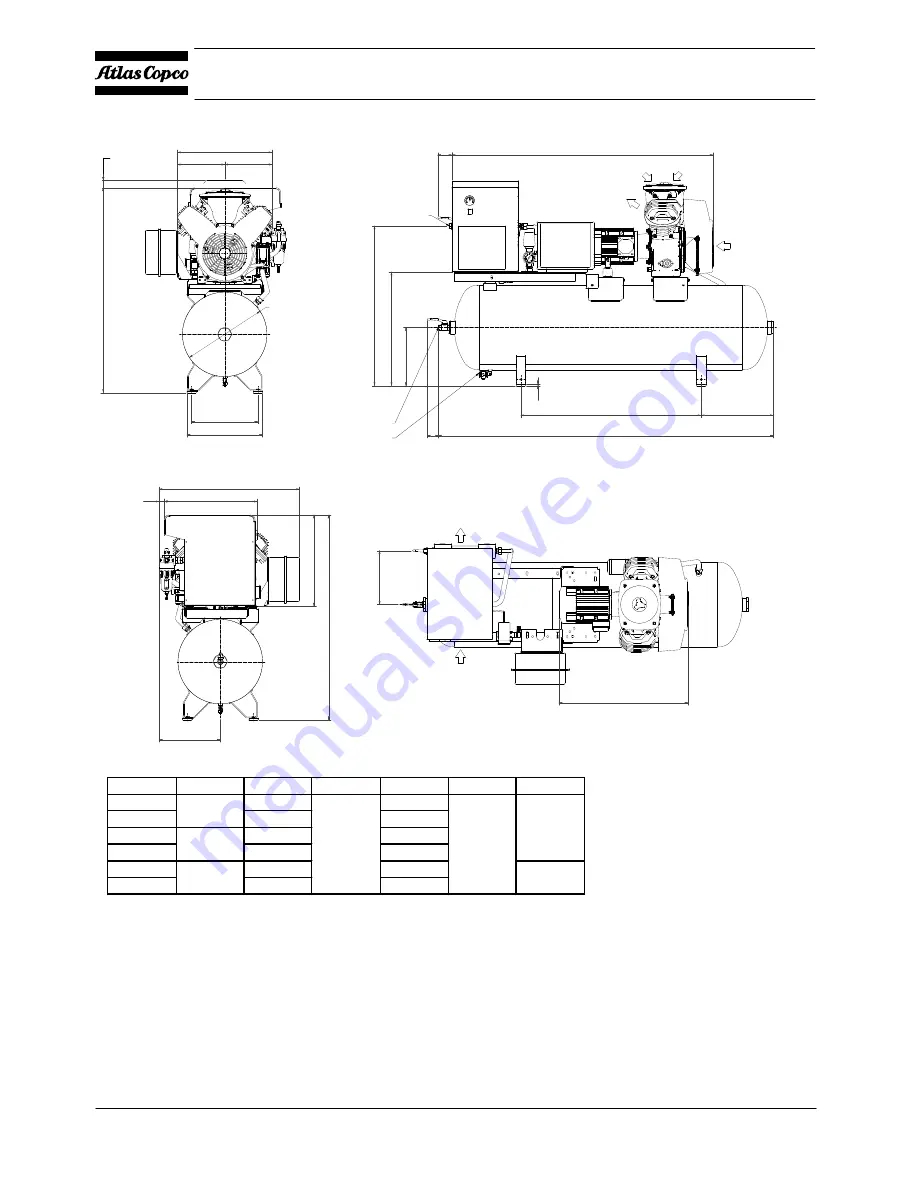

Compressor Air inlet

960

384

1782

450

1390

60

3

1

0

3

1

0

6

0

5

6

H

6

Manual drain outlet G 1/4"

Compressed air outlet G 1/2"

Dryed compressed air outlet G 1/2"

402

5

352

5

8

5

0

6

76

For dismantling

air filter

Cooling air inlet

Cooling air outlet

4

0

A

B

C

748

28

495

1

0

9

0

6

4

8

5

326

2

8

6

Dryer cooling air outlet

Dryer cooling air inlet

D

Type

Net Mass

A

B

C

D

H

LE/LF 2

504

252

LT2

533

279

LE/LF 3

504

252

LT3

533

279

LE5

504

252

LT5

533

279

1072

175 kg

1082

171 kg

177 kg

252

686

LF 2 up to LF 3, Tank-mounted Full-Feature, receiver 250 l

Summary of Contents for LF 10

Page 1: ...Atlas Copco Industrial aluminium piston compressor LF 2 LF 3 LF 5 LF 7 LF 10 Instruction book ...

Page 2: ......

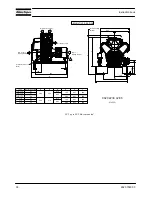

Page 12: ...10 2920 7090 00 Instruction book Power Pack with unloading valve Base mounted ...

Page 18: ...16 2920 7090 00 Instruction book Air flow and regulating system with DOL starter ...

Page 19: ...2920 7090 00 17 Instruction book Air flow and regulating system with Y D starter ...

Page 20: ...18 2920 7090 00 Instruction book Air flow and regulating system of trolley ...

Page 72: ......

Page 73: ......

Page 74: ......