50

2920 7090 00

Instruction book

Period Operation

Daily

Inspect and clean the filter of the steam trap.

Weekly

Brush or blow off the finned surface of the condensor.

Note (Full Feature units):

Regularly check that the condensate is discharged via the condensate outlet of the refrigerant dryer. The

amount depends on the operation conditions.

5.3 Service

kits

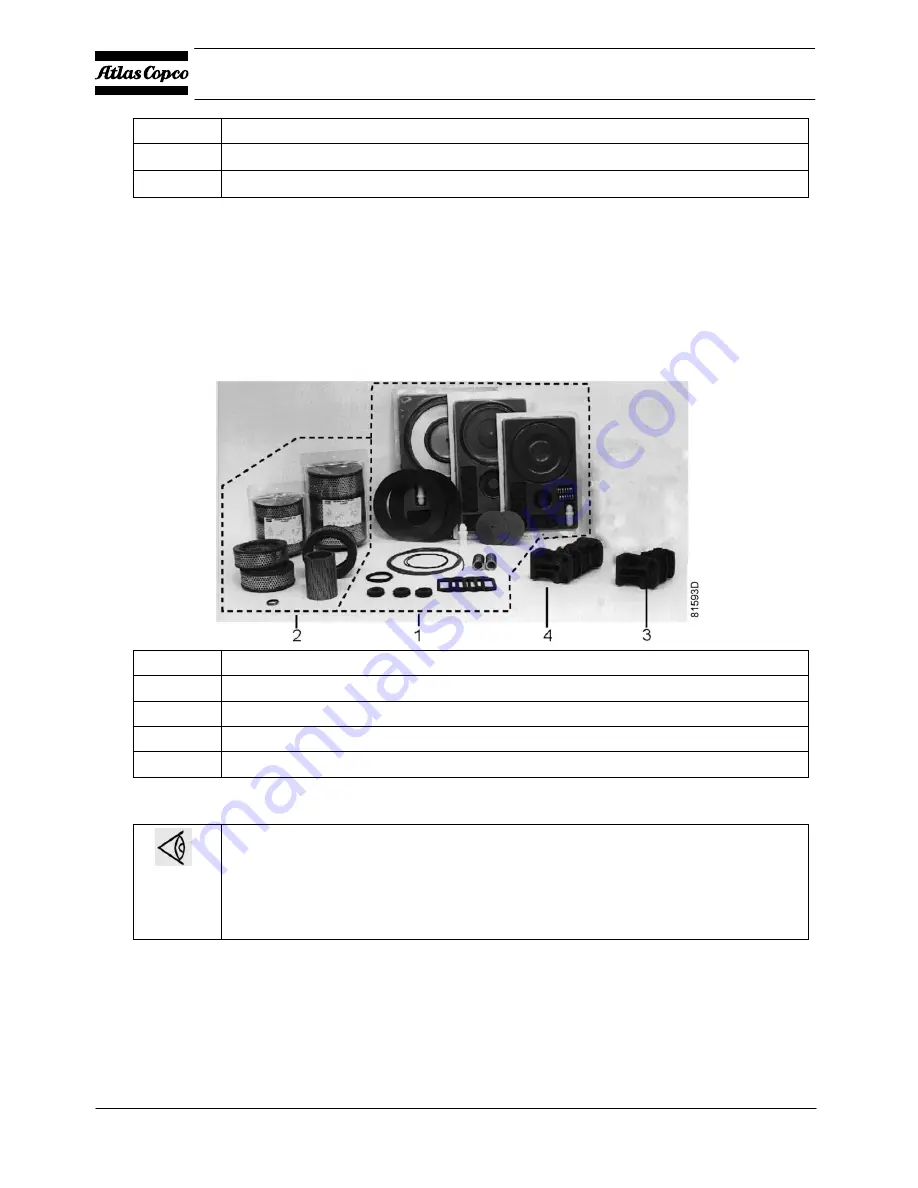

Service kits are available, offering the benefits of genuine Atlas Copco parts while keeping the maintenance

budget low. The kits comprise all parts needed for servicing. Consult the Parts list for the contents of all kits.

Reference Operation

1 Valve

kit

2 Filter

kit

3 Check

valve

4 Unloader

Notes:

1. Use only authorized parts. Any damage or malfunction caused by the use of

unauthorized parts is not covered by Warranty or Product Liability.

2. Whichever interval comes first. The local Sales Company may overrule the

maintenance schedule, especially the service intervals, depending upon the

environmental and working conditions of the compressor.

3. For the contents of all kits, consult the Parts list.

5.4 Disposal of used material

Used filters or any other used material (e.g. desiccant, lubricants, cleaning rags, machine parts, etc.) must be

disposed of in an environmentally friendly and safe manner, and in line with the local recommendations and

environmental

legislation.

Summary of Contents for LF 10

Page 1: ...Atlas Copco Industrial aluminium piston compressor LF 2 LF 3 LF 5 LF 7 LF 10 Instruction book ...

Page 2: ......

Page 12: ...10 2920 7090 00 Instruction book Power Pack with unloading valve Base mounted ...

Page 18: ...16 2920 7090 00 Instruction book Air flow and regulating system with DOL starter ...

Page 19: ...2920 7090 00 17 Instruction book Air flow and regulating system with Y D starter ...

Page 20: ...18 2920 7090 00 Instruction book Air flow and regulating system of trolley ...

Page 72: ......

Page 73: ......

Page 74: ......