6

Maintenance

6.1

Preventive maintenance schedule

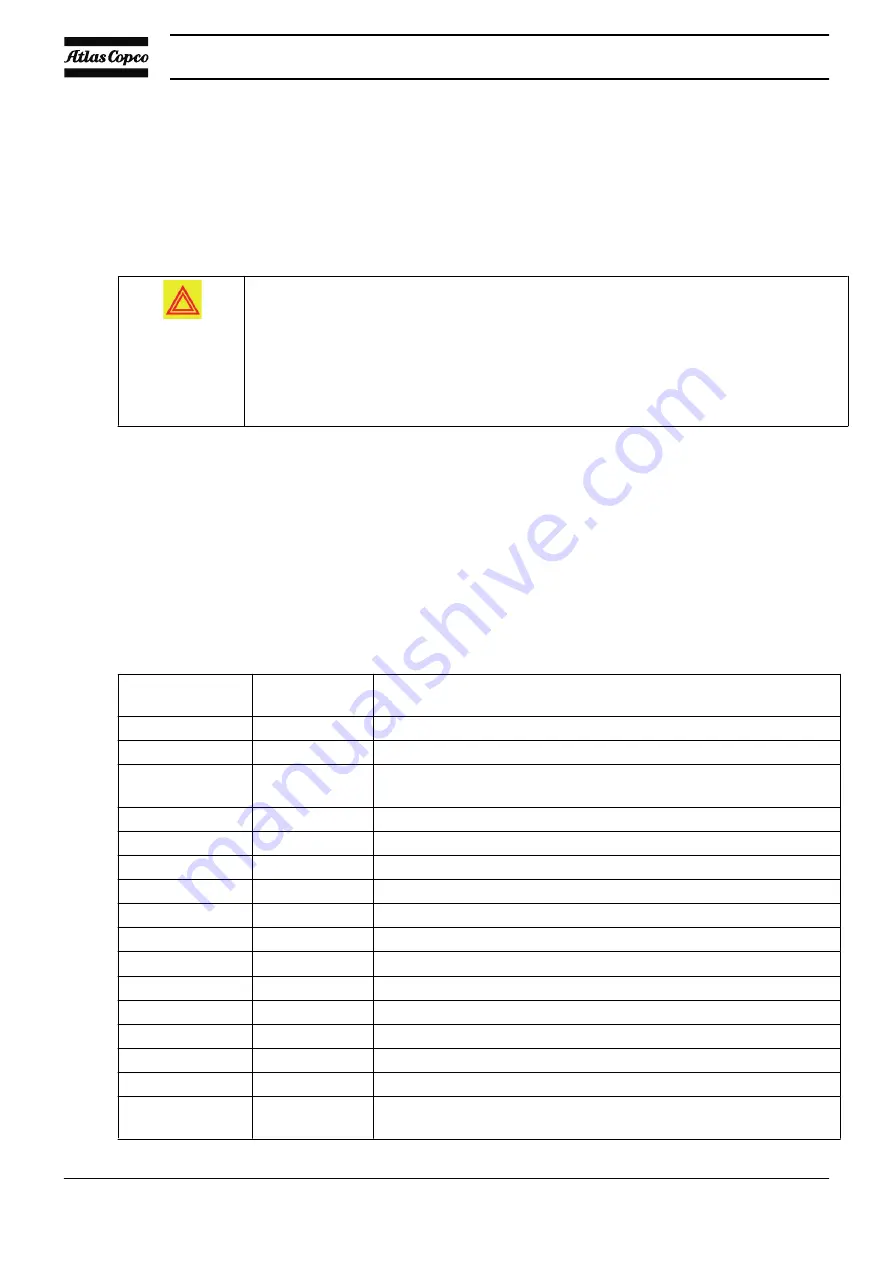

Warning

Before carrying out any maintenance, repair work or adjustment, proceed as

follows:

• Stop the compressor.

• Press emergency stop button (S2).

• Close the air outlet valve and open the manual condensate drain valves.

• Switch off the voltage.

• Open and lock the isolating switch.

The operator must apply all relevant

Warranty - Product Liability

Use only authorized parts. Any damage or malfunction caused by the use of unauthorized parts

is not covered by Warranty or Product Liability.

General

When servicing, replace all removed gaskets, O-rings and washers.

Preventive maintenance schedule

Period 1)

Running hours

1)

Operation

Daily

8

Check readings on display.

Daily

8

Check that condensate is discharged during loading.

Daily

8

Check oil level. Before starting, the level should be in the middle of

the sight-glass.

Weekly

--

Check the cleanliness of the cubicle filters. Replace or clean if dusty.

3-Monthly

--

Clean compressor.

3-Monthly

--

Operate safety valve.

3-Monthly

--

Remove, dismantle and clean float valve of condensate trap(s).

3-Monthly

--

Check for possible leaks.

3-Monthly

500

Check the coolers; clean them if necessary. See section

.

3-Monthly

--

Remove air filter elements and inspect.

Yearly

4000

Change oil.

Yearly

4000

Replace air filter element.

Yearly

4000

Replace oil filters.

Yearly

--

Carry out a LED/display test (see section

Yearly

--

Have all flexibles inspected.

Yearly

--

Have safety valve tested. (To be carried out by an Atlas Copco

representative)

Instruction book

68

APF219617

Summary of Contents for MAS 200

Page 1: ...Instruction book APF219617 MAS 200 ...

Page 2: ......

Page 44: ...Instruction book 42 APF219617 ...

Page 49: ...Electric connections Electrical diagram Instruction book APF219617 47 ...

Page 92: ......

Page 93: ......