24

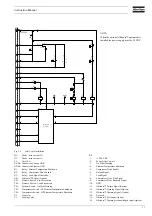

ORV 10 - ORV 12 - ORX 10 - ORX 12

5.2

A

IR

RECEIVER

The air receiver is tested according to official standards. Regularly

have inspections carried out in conformity with local regulations.

5.3

S

AFETY

VALVE

Following checks must be carried out:

–

a check of the opening of the lifting gear, twice a year.

This can be done by screwing the cap of the valve anti-clockwise.

–

a check of the set pressure once a year according to the local

regulations. This check cannot be done on the compressor and

must be carried out on a proper test bench.

5.4

T

EMPERATURE

SHUTDOWN

SWITCHES

The instructions apply to both shutdown switches.

The mechanical condition of the compressor temperature shutdown

switch can be tested by immersing its sensing element in hot oil.

The contact of the compressor temperature switch (

, TS1 and

TS2) should open at the pre-set temperature (see section

). Test by

means of an ohmmeter, or a test lamp with battery, and a

thermometer. Stir the oil during testing.

5.5

A

IR

FILTER

VACUUM

INDICATOR

SWITCH

1. Stop the compressor. Disconnect the wires from the switch and

remove the switch with its coupling from the air intake manifold.

2. Fit the switch to a tee with a female leg of M10x1.5.

Connect a vacuum gauge and a hose or pipe to the other legs.

3. Connect an ohmmeter or a test lamp with battery to the switch.

4. Create a vacuum with the mouth through the hose, while

observing the vacuum gauge and the ohmmeter or test lamp. The

lamp should light up when the vacuum has reached 47-53 mbar.

Change the switch if it does not respond correctly.

5. Reinstall the switch and reconnect the wire.

5.6

S

TART

PREVENTING

PRESSURE

SWITCH

AND

MINIMUM

LOADING

PRESSURE

SWITCH

The switches can be tested on a compressed air line by means of a

pressure-reducing valve, small air receiver, pressure gauge and

ohmmeter or test lamp with battery. The contacts of the switches

should trip at pressures specified in section

6.

OPTIONS

6.1

O

ILTRONIX

™

The OILTRONIX™ is an Electronic Oil Management System for

compressors providing an optimal oil injection temperature that

reduces the condensation of water in the oil. This will result in a

longer life of components in the compressor system.

Daily drain condensate.

All adjustments or repairs are to be done by an

authorized representative of the valve supplier, see

section 1.7 Specific safety precautions.

Summary of Contents for ORV 10

Page 1: ...ORV 10 ORV 12 ORX 10 ORX 12 Instruction Manual for Portable Compressors English ...

Page 2: ......

Page 43: ......