12

PAGE

Repair Instructions Nr.183.09/00

PHE 50 S

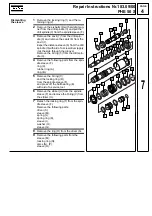

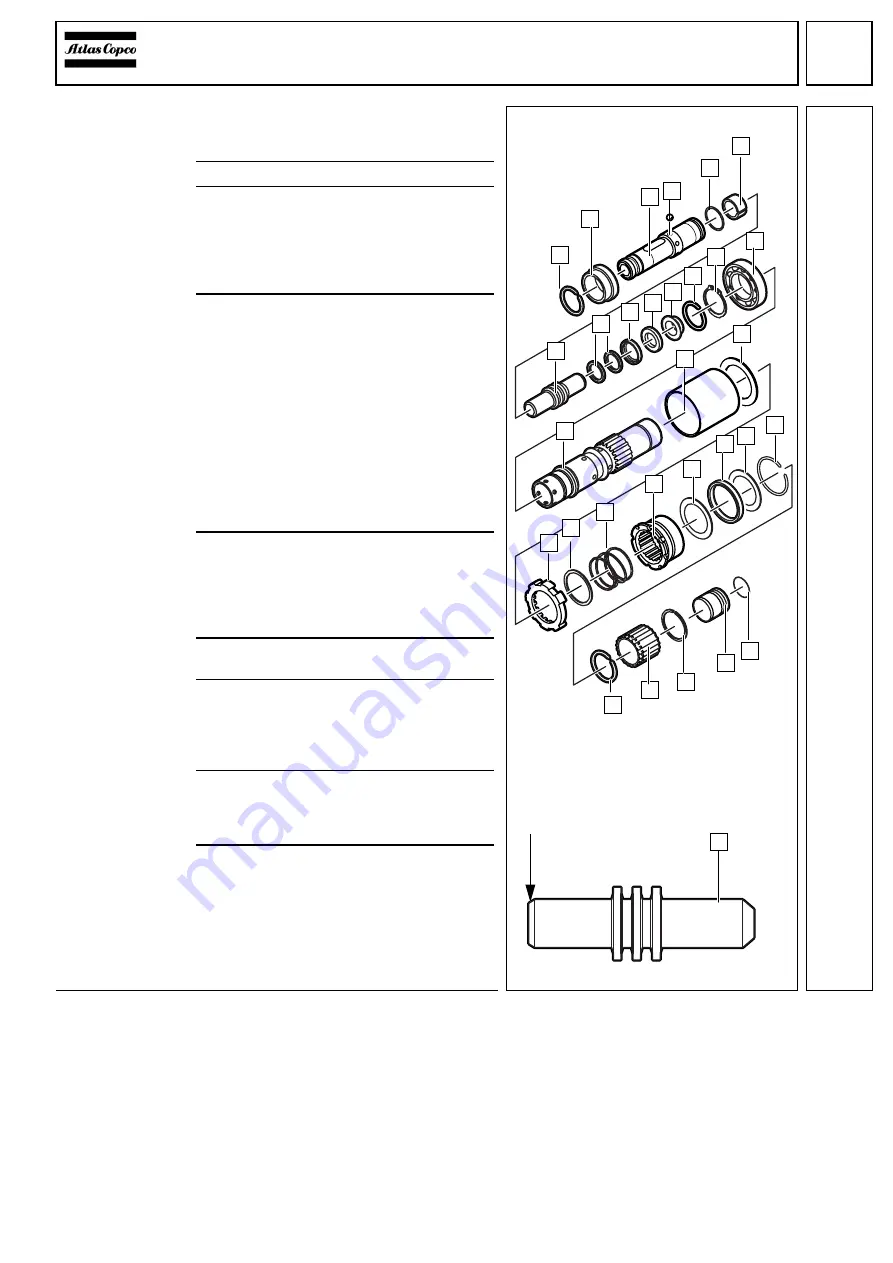

Assembling

the sleeve

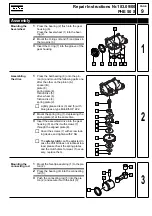

1

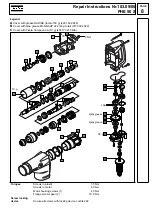

Press the ball bearing (E) onto the spindle

sleeve (F) and fit the locking ring (D) and

the O-ring (C).

2

Mount the ring (R) on the driver (S).

3

Mount the following parts on the

sleeve (M):

disc (N),

sleeve (O),

disc (P).

Insert the locking ring (Q).

4

Mount the following parts on the spindle

sleeve (F):

spring ring (K),

sleeve (G),

spring (L) (pressed over the toothing of the

spindle sleeve (F)),

washer (H),

sleeve (I),

sleeve (M),

driver (S).

☞

Mount the locking ring (T) on the spin-

dle sleeve (F) with aid of the cone

(service tool).

5

Mount the O-ring (V) on the striker (U) and

insert the striker (U) into the spindle

sleeve (F).

☞

The O-ring (V) must face the direction

of the four-lips-seal-ring of the piston.

6

Insert the ring (B), the rubber ring (A) and

the ring (9) into the spindle sleeve (F).

7

Fit the O-ring (5) on the drill spindle (3), in-

sert the distance sleeve (6) into the drill

spindle (3), and fit the seals (8) on the an-

vil (7).

Insert the anvil (7) into the drill spindle (3).

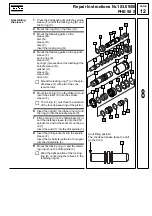

8

Insert the drill spindle (3) into the spindle

sleeve (F).

Insert the six balls (4) with aid of a magnet

into the drill spindle (3).

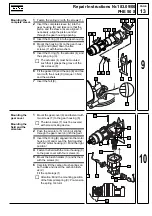

9

Mount the locking ring (1) and the retain-

ing ring (2) on the drill spindle (3).

☞

Mind the right position of the locking

ring (D) concerning the relieves in the

retaining ring (2).

2

1

6

5

4

7

9

B

C

A

D

8

F

H

G

O

N

M

L

K

I

S

V

U

T

3

P

R

E

Q

Anvil fitting position:

The shortened phase faces the drill

(to the front).

7

8

Summary of Contents for PHE 50 S

Page 1: ......