3

PAGE

Repair Instructions Nr.183.09/00

PHE 50 S

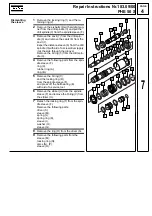

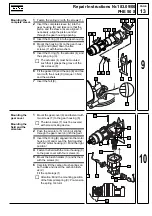

Removing the

field and the

armature,

Removing the

gear cover

1

Pull off the respective cable lugs (1) and

remove the carbon brushes (2) on both

sides by lifting the carbon brush springs.

2

Loosen the screws (A) and detach the

brush holders (3).

3

Loosen the four screws (4).

4

Remove the field together with the motor

housing (9).

The armature (5) will remain in the gear

cover (6).

5

Remove the O-ring (B) from the rubber

sleeve of the armature bearing. Pull out

the armature (5) manually, if necessary

use a plastic hammer for support (light

blows).

6

Undo the two screws (7) in the gear

cover (6) and pull off the gear cover (6).

If needed, remove it with blows with a

plastic hammer.

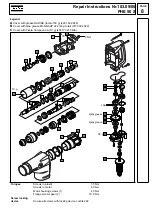

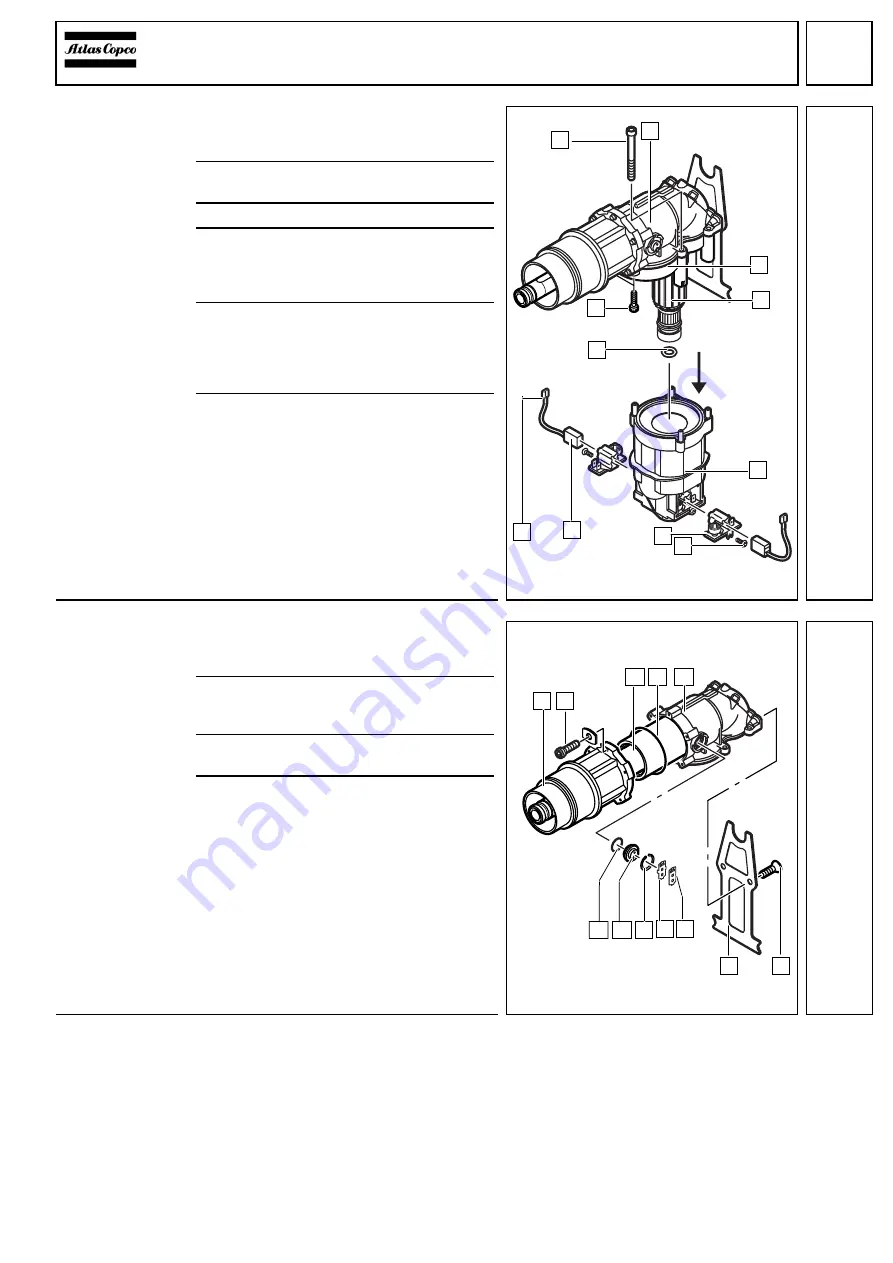

Removing the

complete sleeve

1

Remove the two springs (5) and (6), the

spring ring (7), the actuator (8) and the

O-ring (9).

2

Remove the five screws (3) with their

washers and pull the housing (4) from the

gear housing (B) (the screws are stuck in).

3

Remove the complete spindle sleeve (A).

Remove the O-ring (C).

4

Loosen both screws (1) and remove the

spring (2).

1

4

6

2

3

7

8

9

A

5

B

5

4

1

2

5

3

6

7

8

9

A

B

C

6

Summary of Contents for PHE 50 S

Page 1: ......