8

PAGE

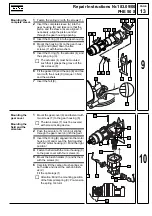

Repair Instructions Nr.183.09/00

PHE 50 S

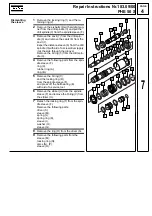

Legend

A

Cover with grease DARINA (total of 50 g) (4931 622 229)

B

Cover with blue grease Mobilith HP 222 (40 g total) (9170 304 322)

C

Cover with Tivela Compound A (10 g) (493170 215 436)

Torques

Screws in plastic

1,5 Nm

Screws in metal

4,0 Nm

Motor housing screws (1)

4,0 Nm

Flange screws gear (2)

10,0 Nm

Screw locking

device

Secure all screws with locking device Loctite 222.

30 g

1

A

B

A

C

A

C

A

2

A

B

B

B

A

C

C

A

30 g

A

10 g

C

A

3 Nm

10 g

A

A

B

B

3 Nm

B

lightly grease

lightly grease

Summary of Contents for PHE 50 S

Page 1: ......