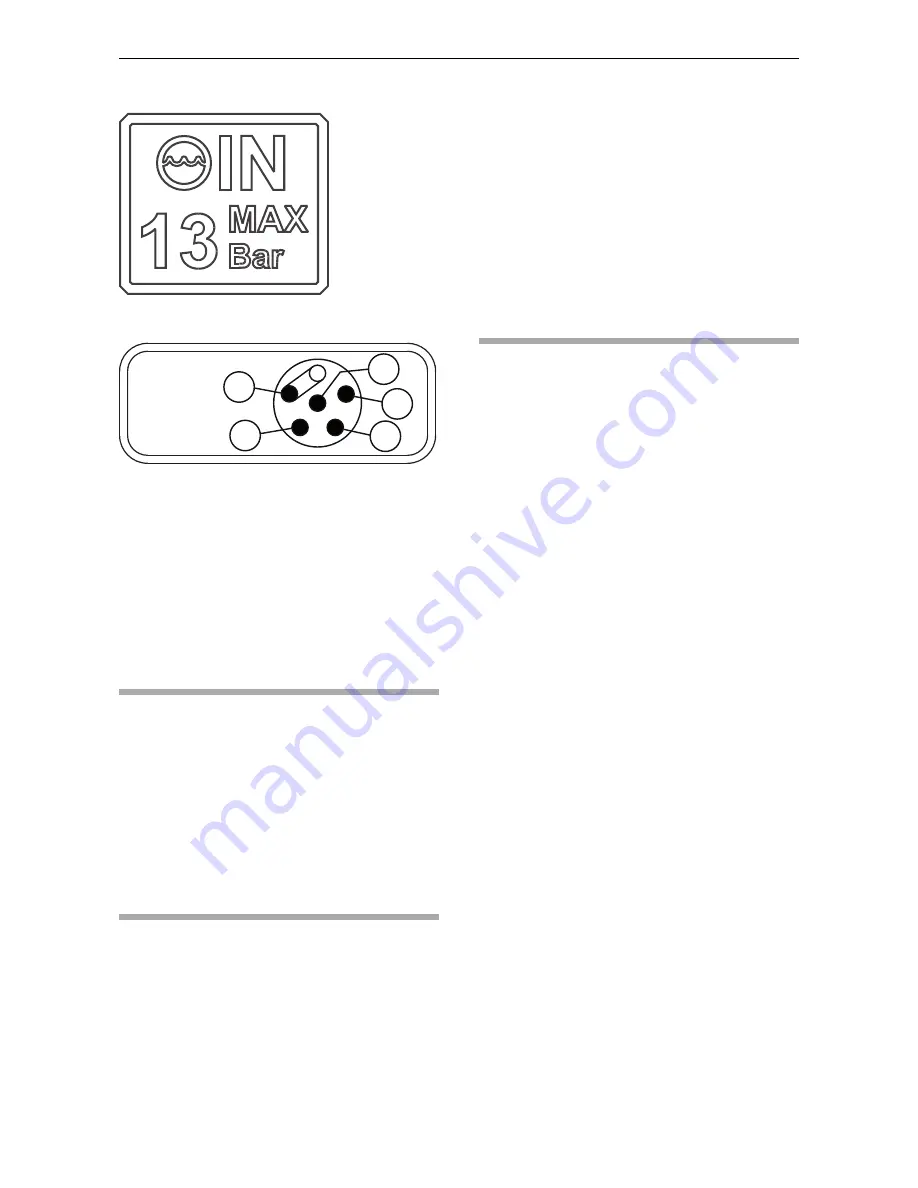

Water pressure label

Electrical connection label

E

P

L1

L2

L3

L1 - Phase 1

L2 - Phase 2

L3 - Phase 3

P - Pilot wire

E - Earth

Installation

Quick-release couplings

The original hydraulic hoses are fitted with Flat-Face

quick-release couplings that are strong and easy to

clean.

NOTICE

Wipe all couplings clean before

connecting. Ensure that couplings are clean and

correctly engaged before operation. Failure to do so

may result in damage to the quick couplings and

cause overheating and cause foreign matter to enter

the hydraulic system.

Hydraulic oil

In order to protect the environment, use of biologically

degradable hydraulic oil (HFD-U) is recommended.

No other fluids must be used.

♦

Viscosity (preferred) 40-50 cSt.

Make sure to only use clean oil and filling equipment.

When the machine is used continuously, the oil

temperature will stabilise at a working temperature

level. This will, depending on the type of work and

the cooling capacity of the hydraulic system, be

between 35-45°C (95-113°F). At working

temperature, the oil viscosity must be within the

preferred limits. The viscosity index indicates the

connection between viscosity and temperature. The

machine must not be used, if oil viscosity fails to

remain within the permitted area, or if the working

temperature of the oil does not fall between 20°C

(68°F) and 60°C (140°F).

Hoses and connections

Connecting hoses

NOTICE

Make sure that the hydraulic oil hoses are

filled before connection.

1. Put the power pack in standby mode by pressing

the On/Off-button.

2. Make sure that the couplings are clean and

operational.

3. Attach the return line hose and the pressure line

hose according to matching colors. The red color

is for pressure line, the blue color is for return

line.

4. Start the unit by pressing the On/Off-button. Run

the power pack to fill up the hydraulic circuit.

Check the hydraulic oil volume, LED 3.

Connecting new hydraulic hoses

Fill up the hoses with oil prior to first usage. The

hoses will require approximately 2 liters (0,53 US

gal) of oil per 10 meter (32,8 feet) hose length.

NOTICE

Empty hoses will drain the power pack of

oil and might prevent it from starting.

1. Connect the pressure and return line hoses to

the power pack and then connect them in a

closed loop.

2. Start and run the power pack for 2 minutes in

idle mode. The oil in the hoses will pass through

the oil filter and will be cleaned.

3. Disconnect the pressure and return line from

each other and connect them to the RD 100.

Disconnecting hoses

1. Put the power pack in standby mode by pressing

the On/Off-button.

2. Remove the feed line hose and the return line

hose.

The couplings are unlocked by moving the collar

back on the coupling.

© 2016 Construction Tools PC AB | No. 9800 1364 01c | 2016-04-06

Original instructions

12

PP 100

Safety and operating instructions