- 110 -

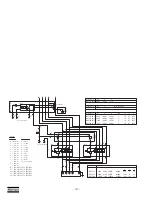

Colour code :

0 = black

1 = brown

2 = red

3 = orange

4 = yellow

5 = green

6 = blue

7 = purple

8 = grey

9 = white

54 = green/yellow

Legend

Wire size :

a = 1

mm²

b =

1.5

mm²

c =

2.5

mm²

d = 4

mm²

e = 6

mm²

f =

10

mm²

g =

16

mm²

h =

25

mm²

i =

35

mm²

j =

50

mm²

k =

70

mm²

l =

95

mm²

jx = 50 mm² EPR-CSP (BS6195-4C)

kx = 70 mm² EPR-CSP (BS6195-4C)

lx = 95 mm² EPR-CSP (BS6195-4C)

nx = 150 mm² EPR-CSP (BS6195-4C)

bx = 1.5 mm² NSGAFOeU

Notes

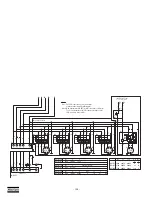

Note 1: The PE-N connection has to be made

at the alternator-side of Circuit

Breaker

Q1.

Breaker Set.

Characteristic dial

Q1

Ir

8

QAS325 Q1

470A

0.75xIn

3.5xIn

QAS275 Q1

400A

1.00xIn

Breaker Set.

Q1

Ir

Ii

OFF

0,1

10

4

0.90xIo

QAS500 Q1

720A

1.00xIn

Breaker Set.

I t²

T2

T1

I2=I3

Q1

Io

I1

nx

0-600A

QAS325

470A

600/5A

kx

lx

0-400A

QAS275

400A

400/5A

jx

2x lx

0-800A

QAS500

720A

800/5A

lx

X

Wire size

Q1

T1-3

P1-3

Z

Summary of Contents for QAS 500 Volvo S2A APP

Page 1: ...QAS 500 Volvo S2A APP Instruction Manual for AC Generators English...

Page 2: ......

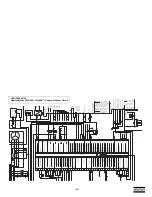

Page 99: ...99 Circuit diagrams...

Page 112: ......

Page 113: ......

Page 114: ...Printed in Belgium 05 2009 2954 3870 00 www atlascopco com...