- 78 -

Maintenance

Maintenance schedule

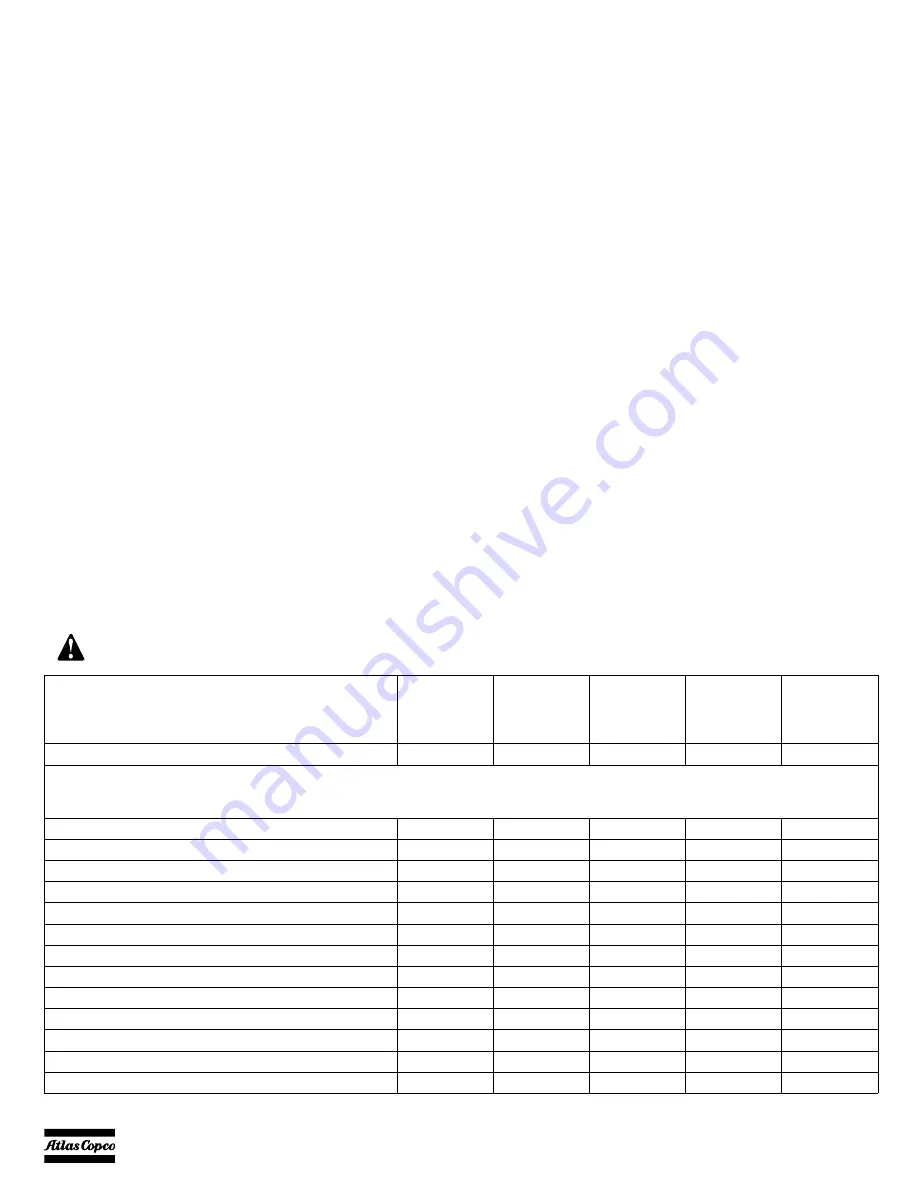

Before carrying out any maintenance activity, check that the start switch is in position O and that no electrical power is present on the terminals.

Maintenance schedule

Daily

Initially

Every 50

hours

Small

Yearly

Every 500

hours

Normal

Every 1000

hours

Every 2

years

Every 2000

hours

Service pak

-

-

2912 4505 04

2912 4506 05

2912 4507 06

For the most important subassemblies, Atlas Copco has developed service kits that combine all wear parts. These service kits offer you the benefits of genuine parts,

save on administration costs and are offered at reduced price, compared to the loose components. Refer to the parts list for more information on the contents of the

service kits.

Check coolant level (1)

x

x

x

x

x

Check oil level in sump

x

x

x

x

x

Check oil pressure on gauge

x

x

x

x

x

Check vacuum indicator

x

x

x

x

x

Check and drain fuel pre-filter/Water separator

x

x

x

Check and clean radiator and intercooler fins

x

x

x

x

Clean air cleaner and dust bowl

x

x

x

x

Check oil, fuel and water leaks

x

x

x

x

Check level battery electrolyte

x

x

x

x

Check condition of vibration dampers

x

x

x

x

Check tension and condition of drive belt(s)

x

x

x

Check and adjust valve clearance (2)

x

x

Check fuel injectors

x

x

Summary of Contents for QAS 500 Volvo S2A APP

Page 1: ...QAS 500 Volvo S2A APP Instruction Manual for AC Generators English...

Page 2: ......

Page 99: ...99 Circuit diagrams...

Page 112: ......

Page 113: ......

Page 114: ...Printed in Belgium 05 2009 2954 3870 00 www atlascopco com...