QMC41-250-I06

EN

Service

© Atlas Copco Industrial Technique AB - 9839 0326 01

11

Service

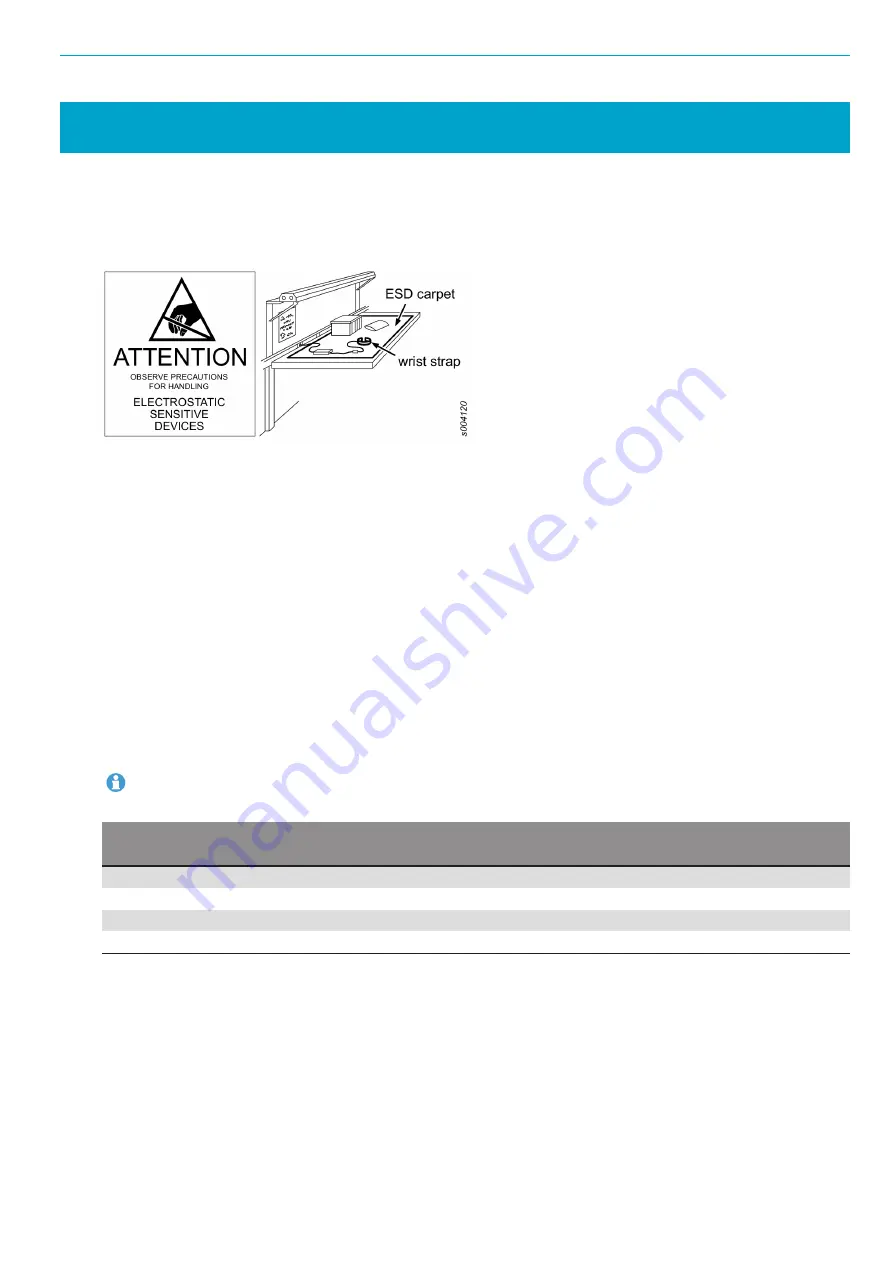

Preventing ESD Problems

The components inside the tool and controller are sensitive to electrostatic discharge. To avoid future mal-

function, make sure that service and maintenance is carried out in an ESD approved work environment.

The figure below shows an example of an appropriate service work station.

Maintenance Instructions

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive

maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guide-

lines:

■

Clean appropriate parts accurately

■

Replace any defective or worn parts

Preventive maintenance

Recommended interval between actions:

Valid at normal usage of the tool at a load up to 70% of maximum torque.

Service should only be carried out by trained technician following provided service instructions and

using original Atlas Copco spare parts.

Interval

Action

1.500.000 cycles or 1 year

Calibrate the tool

1.500.000 cycles

Exchange bit grounding

3.000.000 cycles

Exchange front part

3.000.000 cycles

Exchange motor

Instructions

Service equipment:

■

Normal workshop equipment.

■

Necessary special equipment as shown in the exploded views/tables.

■

For testing a calibration rig is recommended.

■

PC with internet connection to be able to download necessary keys.

Summary of Contents for QMC41-250-I06

Page 8: ...Installation EN QMC41 250 I06 8 Atlas Copco Industrial Technique AB 9839 0326 01 ...

Page 14: ......

Page 15: ......