- 44 -

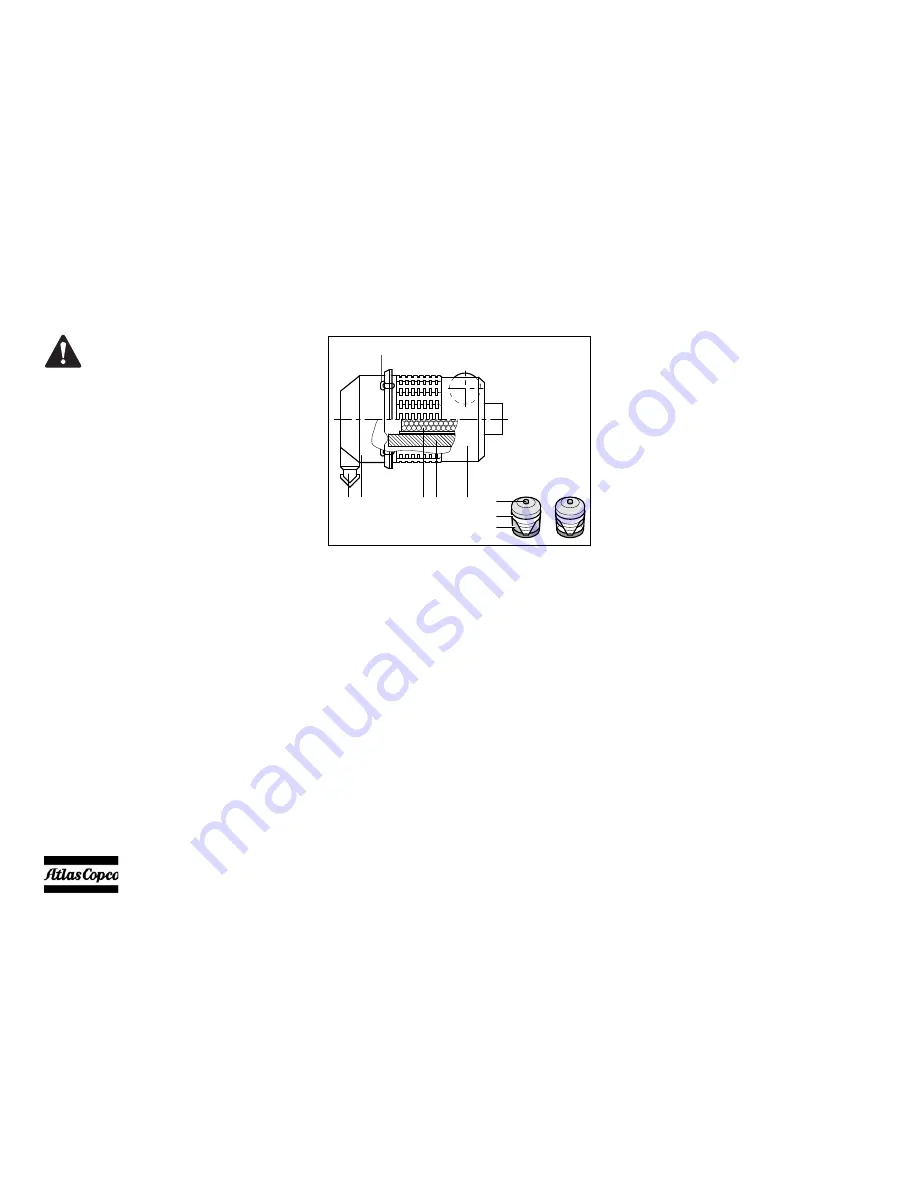

AIR FILTER ENGINE/COMPRESSOR

SERVICING

Always select the service point according to the

vacuum indicator or display message. A regular

inspection or cleaning as it is sometimes practiced in

the field is more likely to be damaging than useful as

there is a risk that the element will be damaged and

dust will gain access to the engine.

Atlas Copco always recommends exchanging

rather than cleaning the filter element in order to

avoid damage and ensure maximum engine

protection.

MAIN PARTS

CLEANING THE DUST TRAP

Remove dust daily.

To remove dust from the dust trap pinch the vacuator

valve (6) several times.

CLEANING INSTRUCTIONS FILTER

ELEMENT

If element cleaning can not be avoided, care should be

taken that the filter element (4) is not washed out.

Please note that engine damage can cause

considerable costs, which makes the cost of a new

filter element seam insignificant.

Safety cartridges (3) can not be cleaned but must be

exchanged.

Please note that a cleaned element will never match

the service life and performance of a new element.

Take the element from the air filter housing (5) (see

section

Replacing the air filter element

).

The Atlas Copco air filters are specially

designed for the application. The use of

non-genuine air filters may lead to

severe damage of engine and/or

compressor element.

Never run the compressor without air

filter element.

1.

Snap clips

6.

Vacuator valve

2.

Dust trap cover

7.

Vacuum indicator

3.

Safety cartridge

(option)

8.

Reset button

4.

Filter element

9.

Yellow indicator

5.

Filter housing

(1)

(6)(2)

(3)(4)

(5)

(7)

(9)

(8)

Summary of Contents for XA(S) 137 DD

Page 2: ......

Page 20: ... 18 CONTINUOUS REGULATING SYSTEM BOV UV UA VH RV AR CE SVa SR ...

Page 70: ... 68 Notes ...

Page 71: ......

Page 72: ...www atlascopco com ...