- 60 -

Notes

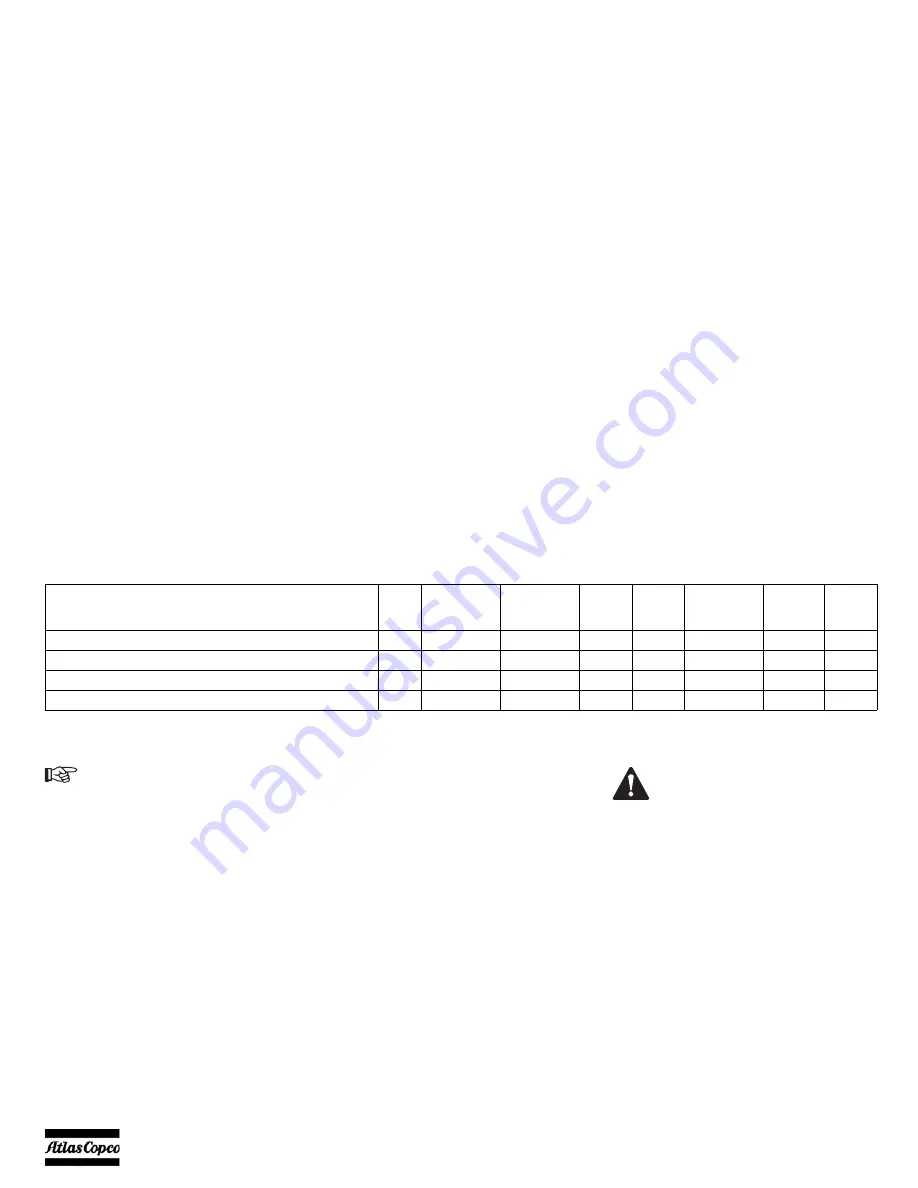

Maintenance schedule (hrs)

(continuation of page 59)

Daily

50 hrs

after initial

start-up

Every

250 hrs

Every

500 hrs

Every

750 hrs

Every

1000 hrs

Every

2000 hrs

Yearly

Grease hinges

x

Analyse coolant (4) (8)

x

Check/Replace safety cartridge

x

Check emergency stop

x

(to be continued on page 61)

1. More frequently when operating in a dusty environment.

2. Refer to engine operation manual.

3. After a day’s work.

4. Yearly is only valid when using PARCOOL. Change coolant every 5 years.

5. Use Atlas Copco oil filters, with by-pass valve as specified in the parts list.

6. Gummed or clogged filters means fuel starvation and reduced engine performance.

7. See section

Oil specifications

.

8. The following part numbers can be ordered from Atlas Copco to check on inhibitors and freezing

points:

2913 0028 00 : refractometer

2913 0029 00 : pH meter.

9. See section

Safety valve

.

10. See section

Before starting

.

11. Replace all rubber flexibles every 6 years.

12. For other specific engine and alternator requirements refer to specific manuals.

13. 250 hours is only valid when using PAROIL E or PAROIL E xtra.

Keep the bolts of the housing, the lifting

eye, the towbar and the axle securely

tightened.

Refer to section Technical specifications

for the torque values.

Summary of Contents for XAHS 447 Cd S3A APP

Page 2: ......

Page 24: ... 24 SH 03 ENGINE CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 25: ... 25 SH 04 CONTROL MODULE 1 2 3 5 9 8 7 6 4 10 A B C D 9822 0963 49 ...

Page 26: ... 26 SH 05 COMPRESSOR CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 27: ... 27 SH 06 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 28: ... 28 SH 07 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 4 10 A B C D E 9822 0963 49 ...

Page 110: ... 110 Notes ...

Page 111: ......

Page 112: ......