I

NSTRUCTION

M

ANUAL

15

MAINTENANCE

P

REVENTIVE

MAINTENANCE

SCHEDULE

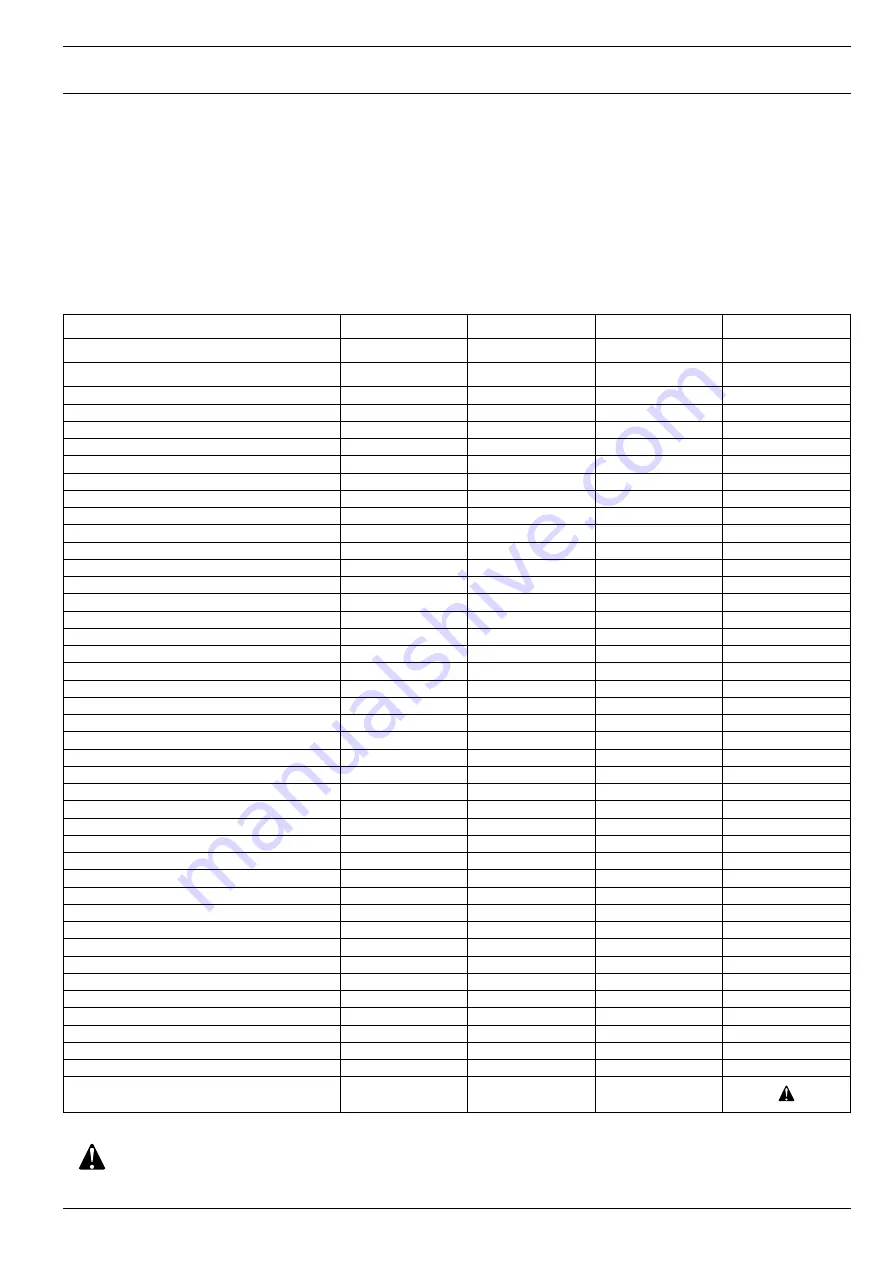

The schedule gives an overview of all maintenance tasks to be

performed on the compressor and includes some engine

maintenance. Refer to maintenance group II of the "Engine Service

Booklet" for full maintenance instructions.

M

AINTENANCE

SCHEDULE

Daily

Weekly

6 Months

Yearly

50 hours

500 hours

1000 hours

SERVICE PAK

-

With unit

2912 4214 05

2912 4216 06

Engine oil level

Check

Check

Check

Check

Engine oil

Change (11)

Change

Change

Engine oil filter (2)

Replace (11)

Replace

Replace

Compressor oil level

Check

Check

Check

Check

Compressor oil (7)

Change

Compressor oil filters (2,8)

Replace (11)

Replace

Coolant level

Check

Check

Check

Check

Air filter dust traps

Empty

Empty

Empty

Empty

Air filter elements (3)

Clean

Clean

Replace

Fuel filters/waterseparator (6)

Drain

Drain

Drain

Drain

Fuel pre-filter element (2,9)

Replace

Replace

Fuel fine-filter element (2,9)

Replace

Replace

Filter element, regulating valve

Replace

Regulating valve, speed regulator, unloader

Check

Check

Pressure drop over oil separator element (10)

Measure

Flow restrictor in oil scavenging line

Clean

Cooler fins

Check/Clean

Check/Clean

Check/Clean

Electrolyte and terminals of batteries

Check

Check

Check

Tension and condition of belts

Check

Check

Check

Routing and condition of flexible hoses

Check

Check

Check

Oil, water, fuel system

Check for leaks

Check for leaks

Check for leaks

Flexible joints and pivots of engine stop solenoid

Lubricate

Lubricate

Lubricate

Flexible joints and pivots of speed regulator

Lubricate

Lubricate

Lubricate

Door hinges, locks

Lubricate

Lubricate

Tightness of bolts and nuts, wheel nuts

Check

Check

Check

Pressure and condition of tyres

Check

Check

Check

Wheel axle suspension arm bearings (5)

Grease

Grease

Drawbar to steering gear shaft (5)

Grease

Grease

Spindle of brake handle (5)

Grease

Grease

Brake system

Check

Check

Wheel hub bearings

Repack

Condition of vibration dampers

Check

Check

Check

Water and sediment in fuel tank (1,6)

Drain

Drain

Compressor bodywork

Clean

Clean

Safety valve (4)

Check

Check/Test

Temperature and oil pressure shutdown switches

Test

Vacuum switch

Test

Engine in/outlet valve clearance

Adjust (11)

Adjust

Engine speed

Check

Check

Check

Check valve spring

Replace

Inspection by Atlas Copco Service technician

Keep the bolts of the housing, the lifting eye, the towbar and the axle securely tightened. Refer to “Technical specifications”

for the torque values.

Keep the wheel brakes properly adjusted.

Summary of Contents for XAHS365 Md

Page 2: ...XAHS365 Md 2 ...

Page 38: ......

Page 39: ...Printed in Belgium 10 2000 2927 1233 03 ...

Page 40: ...Instruction Manual for Portable Compressors XAHS365 Md ...