- 48 -

FUEL SYSTEM

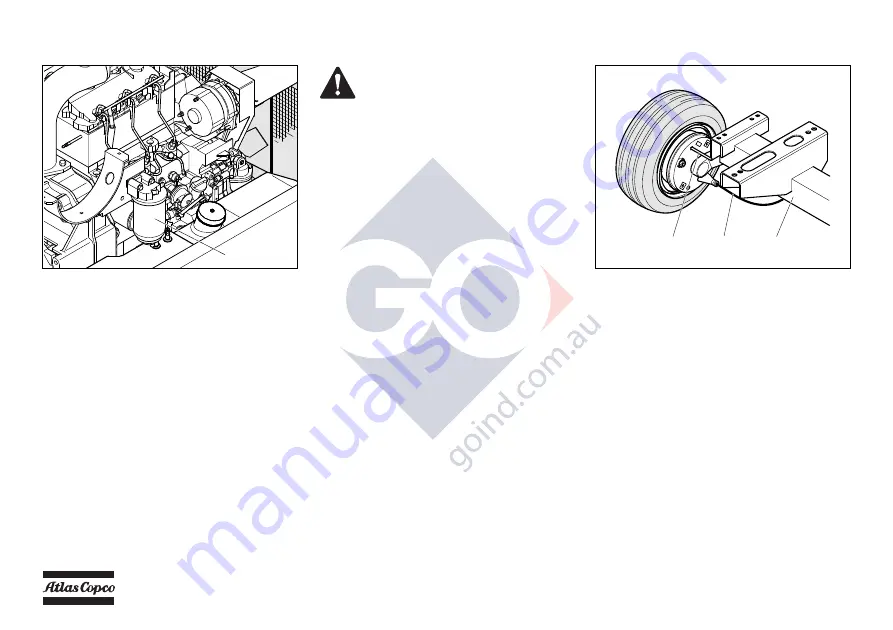

Replacing the filter element

1. Unscrew the filter element (1) from the adapter

head.

2. Clean the adapter head sealing surface. Lightly oil

the gasket of the new element and screw the latter

onto the header until the gasket is properly seated,

then tighten with both hands.

3. Check for fuel leaks once the engine has been

restarted.

BRAKE ADJUSTMENT

BRAKE SHOE ADJUSTMENT

Check the thickness of the brake lining. When the

brake lining has been worn to a thickness of 1 mm

(0.039 in) or less, the brake shoes have to be replaced.

Lift and support the compressor. Make sure that all

brakes are off (overrunbrake and hand brake lever).

The brake cables must be free from tension. Lock the

swivel cams of the wheel brake from the outside by

means of a pin

∅

4 mm (3) through the hole as shown

in the Figure.

Turn the adjustable machine part inside the wheel till

the wheel locks up. Center the brake shoes by

actuating the parking brake several times.

Turn the adjusting machine part anti-clockwise until

the wheel is running free in direction of travel

(approx. 1 full turn of the adjusting bolt).

Check the position of the equalizer (see section

, 6) with the parking brake

actuated.

Perpendicular position of equalizer = identical

clearance of wheel brakes.

Re-adjust the brake shoes, if necessary.

(1)

Before jacking up the compressor,

connect it to a towing vehicle or attach a

weight of minimum 50 kg (110 lb) to the

towbar.

1.

Axle

2.

Brake cable

3.

Pin (

∅

4 mm or similar tool such as screwdriver)

(2)

(1)

(3)

Summary of Contents for XAS 185 DD7

Page 2: ......

Page 22: ... 20 CONTINUOUS REGULATING SYSTEM UV UA VH RV SR AR CE ...

Page 67: ......

Page 68: ...www atlascopco com Atlas Copco Instruction Manual ...