- 19 -

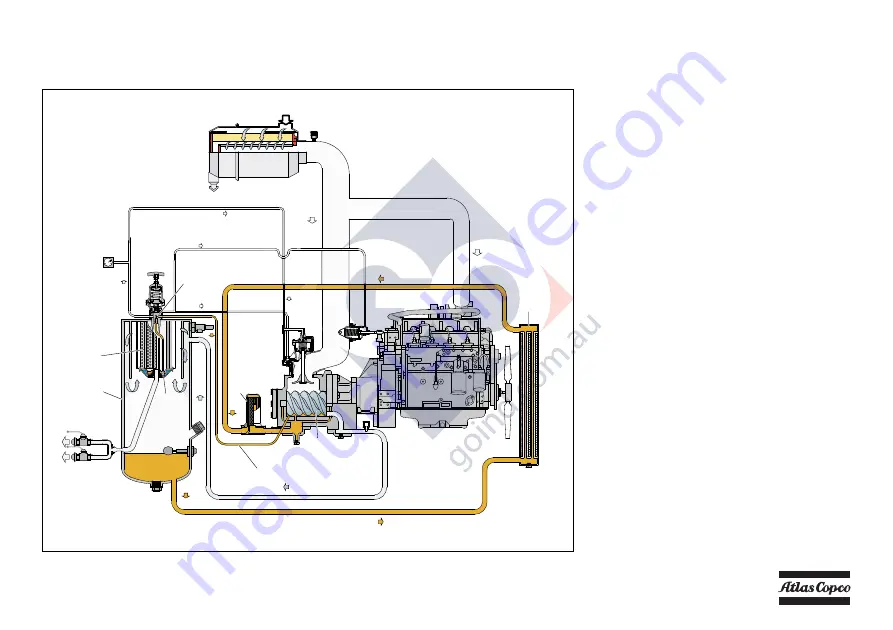

OIL SYSTEM

The lower part of the air receiver (AR) serves as oil

tank.

Air pressure forces the oil from the air receiver/oil

separator (AR/OS) through the oil cooler (OCce) and

oil filter (OF) to the compressor element (CE).

When the compressor is stopped and / or there is no

pressure in the system, the oil stop valve (OSV)

prevents the oil from flowing back into the

compressor element.

The compressor element has an oil gallery in the

bottom of its casing. The oil for rotor lubrication,

cooling and sealing is injected through holes in the

gallery.

Lubrication of the bearings is ensured by oil injected

into the bearing housings.

The injected oil, mixed with the compressed air,

leaves the compressor element and re-enters the air

receiver, where it is separated from the air as

described in section

. The oil that collects in

the bottom of the oil separator element is returned to

the system through a scavenging line (SL), which is

provided with a flow restrictor (FR).

The oil filter by-pass valve opens when the pressure

drop over the filter is above normal because of a

clogged filter. The oil then by-passes the filter

without being filtered. For this reason, the oil filter

must be replaced at regular intervals (see section

Preventive maintenance schedule for the

compressor

When cold start equipment is installed, a thermostatic

valve will bypass the compressor oil (oil will not pass

through oil cooler OCce), until the working

temperature is reached.

(FR)

(AR)

(SL)

(OF)

(OCce)

(OS)

(CE)

(SL)

Summary of Contents for XAS 185 DD7

Page 2: ......

Page 22: ... 20 CONTINUOUS REGULATING SYSTEM UV UA VH RV SR AR CE ...

Page 67: ......

Page 68: ...www atlascopco com Atlas Copco Instruction Manual ...