- 21 -

Operating instructions

Parking, towing and lifting instructions

Safety precautions

Attention

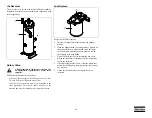

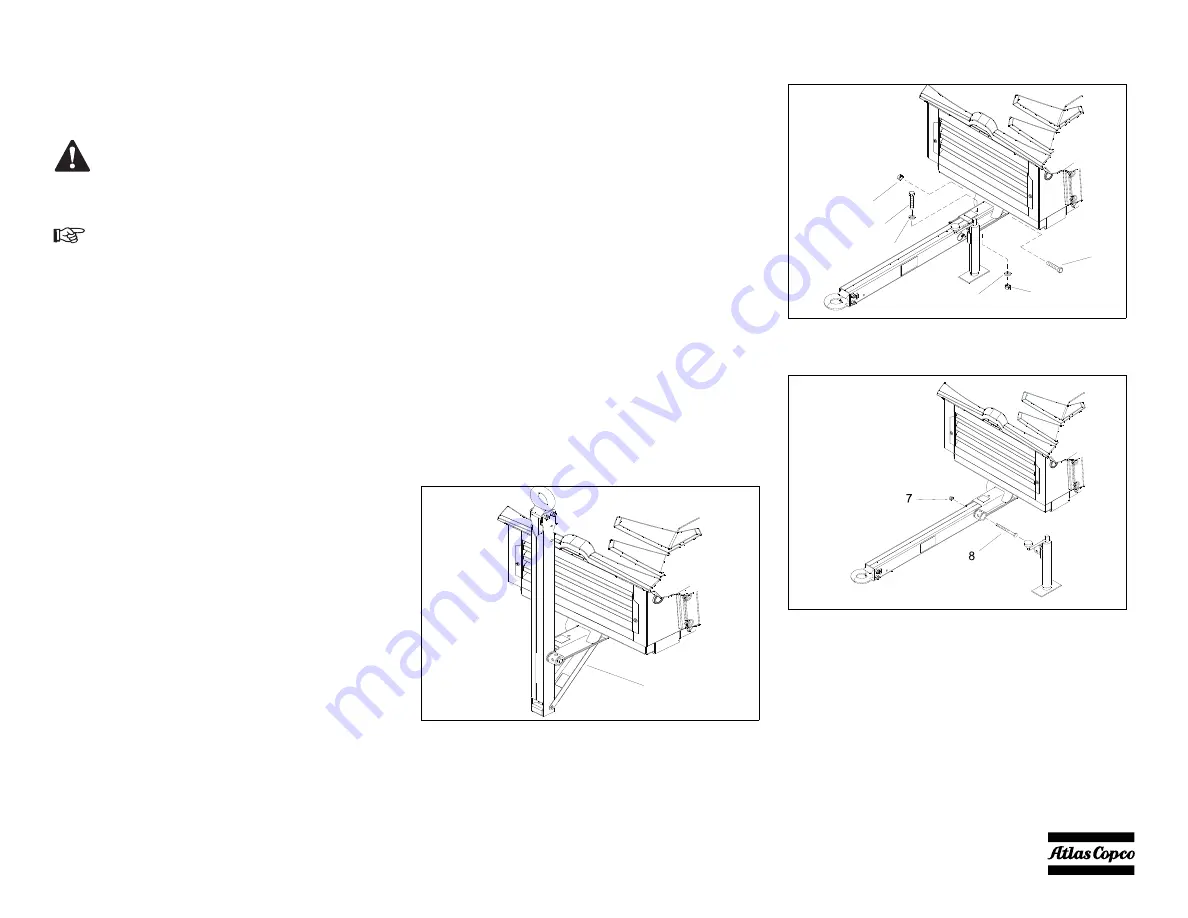

DRAWBAR PREPARATIONS FOR TOWING

Atlas Copco XAS 185 KD7 compressors may be supplied

to a customer with a folded drawbar. The drawbar is

positioned in it’s upright position for shipping purposes

only. When the compressor is received by the end

customer, the drawbar will need to be put into it’s

operating position. To do this:

1. With the weight of the compressor still on the drawbar,

pull the pin on the jacking device (prop or nose wheel)

and move it into the down position. Be sure to re-

insert the pin to keep the jack locked in place.

2. Use the jack to support the compressor in a level

position by turning the handle at the top of the jack.

3. Using the appropriate tools, remove the shipping

bracket and fold the drawbar into it’s down position.

Disgard locknut.

Note:

take the necessary precautions as to not pinch

the wire harness that runs through the drawbar during

the unfolding process. Pull the excess harness out

through the front of the drawbar.

4. Reuse the shipping bracket bolt to secure the drawbar

by reinserting the bolt through both drawbar halves

(item 2, 3). Secure and tighten with the locknut sup-

plied in the shipping bag. Torque the nut and bolt to

130 ft-lbs.

5. Using a jack stand or by blocking, support the end of

the drawbar. With the compressor properly supported

remove the prop or nose wheel and tighten the pivot

nut/bolt. Torque the nut and bolt to 130 ft-lbs.

6. Re-attach the prop to the drawbar in the down posi-

tion and install keeper pin. Jack the unit up with the

prop to remove the blocking.

7. Using bolt, washers, and locknut (items 4,5,6) from

shipping bag, insert bolt through hole on top of draw-

bar using washers and secure with locknut. Torque

nut and bolt to 130 ft-lbs.

8. Discard any remaining hardware and the shipping

bracket.

9. Retorque the all drawbar attachment bolts to their

specified value after 5-10 hours of use.

Note:

the pivoting feature of the drawbar is for

shipping purposes only. The drawbar is to remain in

the down position after it’s initial setup.

REUSE OF

LOCKNUTS IS STRICTLY PROHIBITTED BY

ATLAS COPCO

The operator is expected to apply all

relevant Safety precautions for portable

Check and retighten the wheel nuts and

drawbar bolts to the specified torque. See

section Technical Specifications.

1

3

2

4

5

5

6

Summary of Contents for XAS 185 KD7 IT4

Page 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Page 2: ......

Page 13: ... 13 Main Parts ...

Page 15: ... 15 Compressor regulating system Load Condition ...

Page 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

Page 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

Page 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Page 40: ... 40 ...

Page 41: ......

Page 42: ...www atlascopco com ...