- 23 -

PARKING INSTRUCTIONS

When parking a compressor, secure prop (1) or nose wheel

to support the compressor in a level position. Place the

compressor as level as possible; however, it can be

operated temporarily in an out-of-level position not

exceeding 15°. If the compressor is parked on sloping

ground, immobilize the compressor by placing wheel

chocks in front of or behind the wheels. Locate the

compressor upwind, away from contaminated wind-

streams and walls. Avoid recirculation of exhaust air from

the engine. This causes overheating and engine power

decrease.

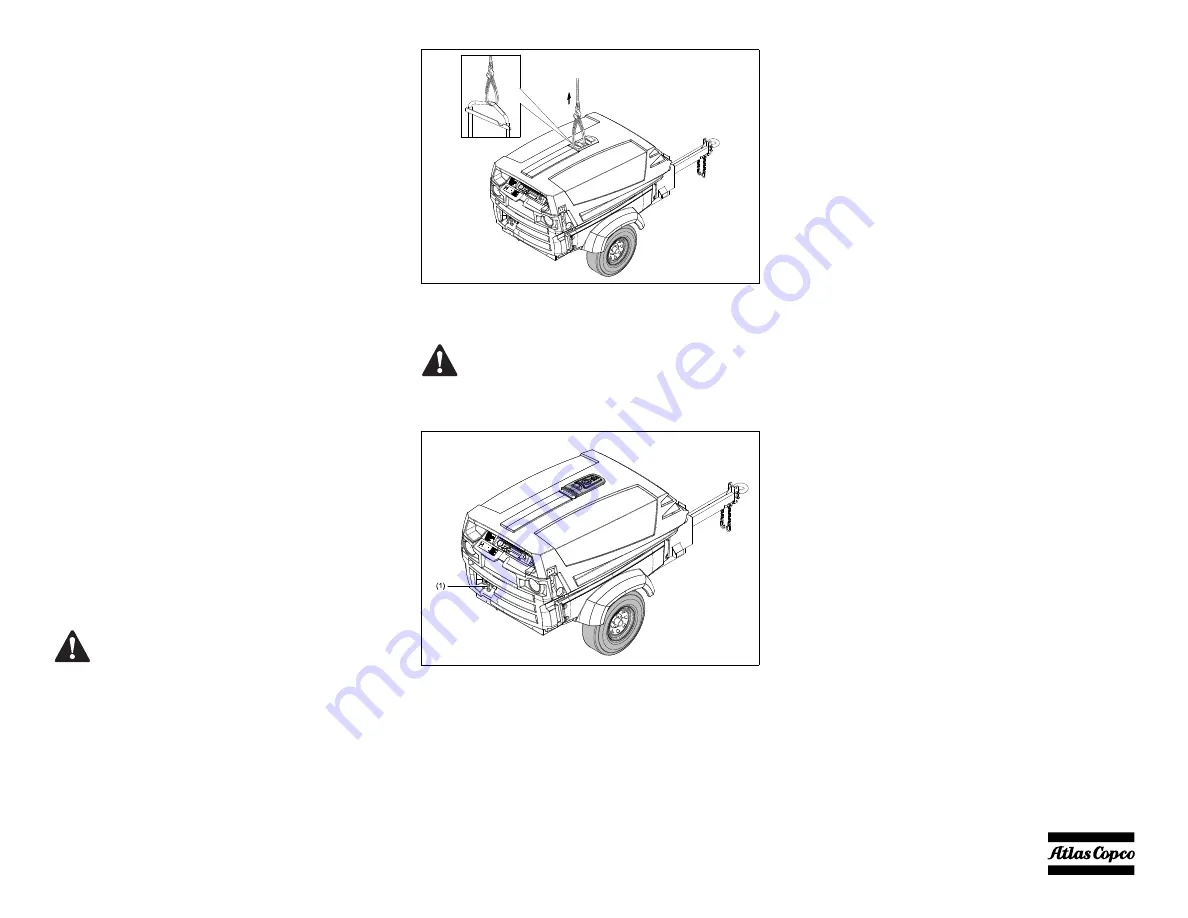

TOWING INSTRUCTIONS

Before towing the compressor, make sure that the towing

equipment of the vehicle matches the towing eye or ball

connector

The drawbar should be as level as possible and the

compressor and towing eye end in a level position. Secure

nose prop (1) in the highest position. Attach safety chains/

cables in a crisscross manner to the tow vehical. This will

help prevent the towbar from contacting ground in event

of a breakaway. Connect road lights when applicable.

LIFTING INSTRUCTIONS

When lifting the compressor, the hoist has to be placed in

such a way that the compressor, which must be placed

level, will be lifted vertically. Use the lifting bale provided

to lift the unit

Before Starting

1. Before initial start-up, prepare battery for operation if

not already done.

2. With the compressor standing level, check the level of

the engine oil. Add oil, if necessary, to the upper mark

on dipstick. Consult the Engine Operation Manual for

the type and viscosity grade of the engine oil.

3. Check the level of the compressor oil. The pointer of oil

level gauge (OLG) should register in the green range.

Add oil if necessary.

4. Check that the fuel tank contains sufficient fuel. Top

up, if necessary. Consult the Engine Operation Man-

ual for the type of fuel.

5. Check coolant level in overflow bottle. Top off coolant

if necessary. Consult engine’s operation manual for

water/coolant specifications.

6. Drain any water and sediment from the fuel filter until

clean fuel flows from the drain cock.

7. Press vacuator valve (VV) of the air filter to remove

dust.

8. Check the air filter service indicator (VI). If the red part

shows completely, service or replace the filter element.

Reset the indicator.

9. Open an air outlet valve (AV) to allow air flow to the

atmosphere.

Lifting acceleration and retardation must

be kept within safe limits (max. 2g).

Helicopter lifting is not allowed.

If the compressor is to be connected to a

common compressed air system, fit an

appropriate check valve between

compressor outlet and air system. Observe

the right mounting position/direction!

Summary of Contents for XAS 185 KD7 IT4

Page 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Page 2: ......

Page 13: ... 13 Main Parts ...

Page 15: ... 15 Compressor regulating system Load Condition ...

Page 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

Page 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

Page 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Page 40: ... 40 ...

Page 41: ......

Page 42: ...www atlascopco com ...