Summary of Contents for XAS 185 KD7 IT4

Page 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Page 2: ......

Page 13: ... 13 Main Parts ...

Page 15: ... 15 Compressor regulating system Load Condition ...

Page 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

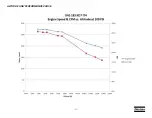

Page 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

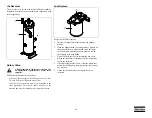

Page 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Page 40: ... 40 ...

Page 41: ......

Page 42: ...www atlascopco com ...