- 75 -

REPLACING THE COOLANT

Drain

Completely drain the entire cooling system.

Used coolant must be disposed or recycled in

accordance with laws and local regulations.

Flush

Flush twice with clean water. Used coolant must

be disposed or recycled in accordance with laws

and local regulations.

From the Atlas Copco Instruction book, determine

the amount of PARCOOL EG required and pour

into the radiator top tank.

It should be clearly understood that the risk for

contamination is reduced in case of proper

cleaning.

In case a certain content of ‘other’ coolant

remains in the system, the coolant with the lowest

properties influences the quality of the ‘mixed’

coolant.

Fill

To assure proper operation and the release of

trapped air, run the engine until normal engine

operation temperature is reached. Turn off the

engine and allow to cool.

Recheck coolant level and add if necessary.

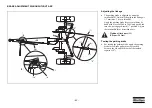

CLEANING COOLERS

Keep the coolers (1), (2) and (3) clean to maintain the

cooling efficiency.

Service doors (4) are provided on both sides of the fan

cowl to allow easy access to the fan side surface of the

coolers.

Clean by air jet in the direction of the arrow.

Steam cleaning in combination with a cleansing agent

may be applied (do not use jet at max. power).

Close the service door(s).

Caution: do not top off when the engine

is hot.

Remove any dirt from the coolers with a

fibre brush. Never use a wire brush or

metal objects.

(1)

(2)

(3)

(4)

To avoid damaging the coolers, angle

between jet and coolers should be

approx. 90 °.

Protect the electrical and controlling

equipment, air filters, etc. against

penetration of moisture.

Never leave spilled liquids such as fuel,

oil, coolant and cleansing agents in or

around the compressor.

Summary of Contents for XRHS 1150 CD4 C3 WUX

Page 2: ......

Page 16: ... 16 Main parts ...

Page 18: ... 18 REGULATING SYSTEM ...

Page 21: ... 21 ELECTRIC SYSTEM 9822 0963 40 C13 HP ...

Page 105: ......

Page 106: ...www atlascopco com ...