- 104 -

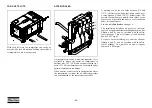

Maintenance Log

Compressor

..........................................................................................

Customer

...............................................................................................

Serial number

........................................................................................

................................................................................................................

Service hours

Maintenance action

Date

By initials

Summary of Contents for XRHS 1150 CD4 C3 WUX

Page 2: ......

Page 16: ... 16 Main parts ...

Page 18: ... 18 REGULATING SYSTEM ...

Page 21: ... 21 ELECTRIC SYSTEM 9822 0963 40 C13 HP ...

Page 105: ......

Page 106: ...www atlascopco com ...