- 81 -

MAINTENANCE QUICK ACTION FUEL COUPLINGS

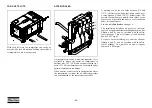

Even with proper selection and installation, quick

action coupling life may be significantly reduced

without a continuing maintenance program.

Frequency should be determined by the severity of

the application and risk potential. A maintenance

program must be established and followed by the user

and must include the following as a minimum:

Visual inspection of quick action couplings:

Any of the following conditions require immediate

shut down and replacement of the quick action

coupling:

Cracked, damaged, or corroded quick action

coupling parts.

Leaks at the fitting, valve or mating seal.

Broken coupling mounting hardware, especially

breakaway clamps.

Visual inspection all other:

Leaking seals or port connections.

Excess dirt build-up on the coupling locking

means or on the interface area of either coupling

half.

Defective clamps, guards, and shields.

Fuel level system and any entrapment.

Functional test:

Operate the system at maximum operating pressure

and check for possible malfunctions and freedom

from leaks. Personnel must avoid potential hazardous

areas while testing and using the system.

Replacement intervals:

Specific replacement intervals must be considered

based on previous service life, government or

industry recommendations, or when failures could

result in unacceptable downtime, damage or injury

risk.

Summary of Contents for XRHS 1150 CD4 C3 WUX

Page 2: ......

Page 16: ... 16 Main parts ...

Page 18: ... 18 REGULATING SYSTEM ...

Page 21: ... 21 ELECTRIC SYSTEM 9822 0963 40 C13 HP ...

Page 105: ......

Page 106: ...www atlascopco com ...