- 70 -

Adjustments and servicing procedures

Single pressure system

The working pressure is determined by the tension of

the spring in the regulating valve (RV). This tension

can be increased to raise the pressure and decreased to

lower it by turning the adjusting wheel clockwise and

anti-clockwise respectively.

To adjust the normal working pressure, proceed as

follows:

1. Loosen the lock nut of the regulating valve.

2. Release Regulating Valve (turn out).

3. With the outlet valves (AOV) closed, adjust the

regulating valve (RV), until a pressure is reached

of nominal pr 2 bar (+ 29 psi).

4. Lock the regulating valve (RV) by fixing the lock

nut.

Dual pressure system (option for XRXS and

XRYS)

The dual pressure system has two regulating valves

marked with I and II and a switch at the rear for

selecting the lower (I) or higher (II) working

pressure.

Set the regulating valve (RV) marked with I at a

working pressure lower than the regulating valve

marked with II. This means the handle of RV I should

be scewed in less than the handle of RV II. This

pressure setting is very important. When done

otherwise the system will not work correctly.

When RV I is set at a working pressure of maximum

25 bar (363 psi), the rpm will increase to 1900 rpm

(instead of 1800 rpm) to deliver more FAD at this

“lower” pressure. RV I can be set at a pressure higher

than 25 bar (363 psi), but then there will be no speed

increase.

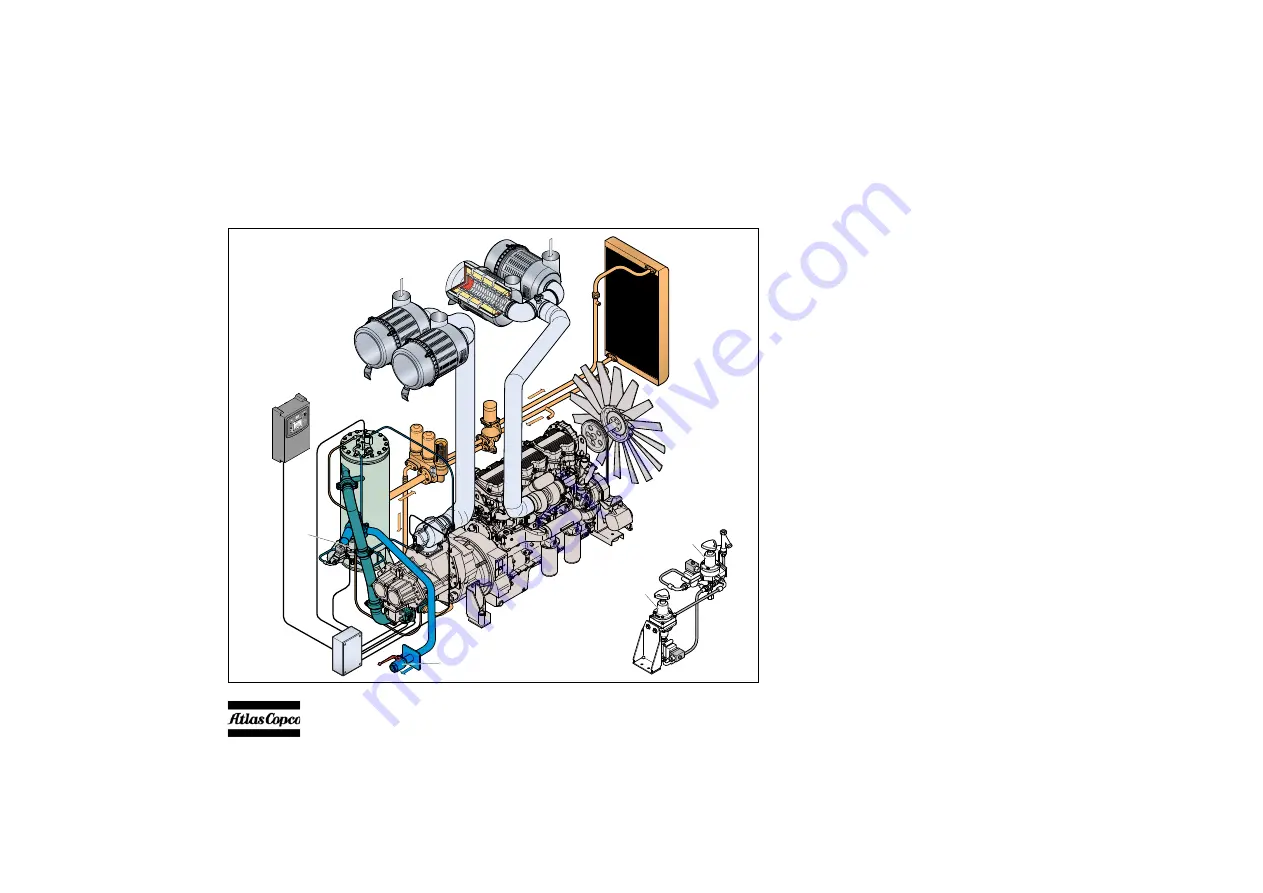

ADJUSTMENT OF THE PNEUMATIC REGULATING SYSTEM

(RV)

(AOV)

(

II

)

(

I

)

(RV)

Summary of Contents for XRVS 1300 CD7

Page 2: ......

Page 20: ... 20 PNEUMATIC REGULATING SYSTEM AR RV CEhp CElp BOV TV UA ...

Page 95: ...Dataplate 95 ...

Page 100: ... 100 ...

Page 101: ......

Page 102: ......