- 118 -

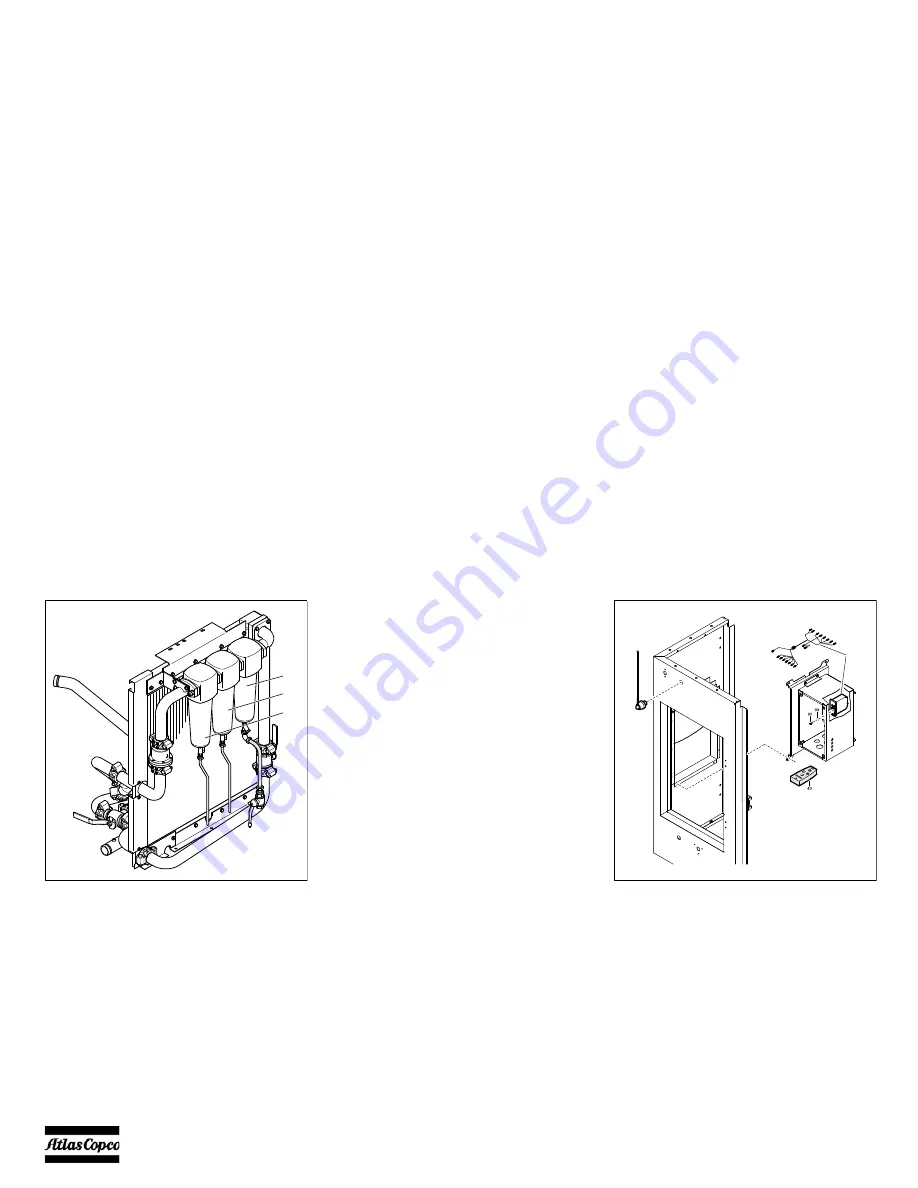

AFTER-COOLER

An integral after-cooler, with water separator (1), is

available to reduce the outlet air temperature to

ambient plus 10°C (18°F) and cut water content to a

mere 15%. This performance can be obtained under

optimal atmospheric conditions.

When an after-cooler is used in an application where

the temperature is critical the air outlet temperature

can be monitored by the compressor controller.

A warning can be set at a value between 0°C and

115°C (=default value) and a shut-down can be set at

a value between 0°C and 120°C (= default value). The

operator has authority to modify these values so the

process can be guarded and kept in a safe condition

under all circumstances.

See also table

Fault codes

on page 73.

The installation includes a by-pass over the after-

cooler. For applications that demand quality air, a fine

filtration unit (2) can be specified with the after-

cooler package. This will remove oil and particles

down to 0.01 mg/m

3

.

For purer, but not breathing, air, an active charcoal

filtration unit (3) can be specified with the after-

cooler package. This removes oil and oil vapour

content to 0.003 mg/m

3

.

REMOTE START

The remote start allows the user to start, stop the

compressor and switch to load/noload by radiosignal.

This is particularly comfortable when the compressor

can not be positioned directly at the job site because

of blocking by buildings or other obstacles.

(1)

(2)

(3)

Summary of Contents for XRVS 1350

Page 2: ......

Page 24: ... 24 FLOW DIAGRAM EXHAUST AFTERTREATMENT HPFP DOC EAM DPF ...

Page 30: ... 30 SH4 COMPRESSOR CIRCUIT 9822 0963 68 ...

Page 135: ......

Page 136: ......