12. The electrical connections must correspond to the applicable codes. The machines must be

earthed and protected against short circuits by fuses in all phases. A lockable power

isolating switch must be installed near the compressor.

13. On machines with automatic start/stop system or if the automatic restart function after

voltage failure is activated, a sign stating "This machine may start without warning" must be

affixed near the instrument panel.

14. In multiple compressor systems, manual valves must be installed to isolate each

compressor. Non-return valves (check valves) must not be relied upon for isolating pressure

systems.

15. Never remove or tamper with the safety devices, guards or insulation fitted on the machine.

Every pressure vessel or auxiliary installed outside the machine to contain air above

atmospheric pressure must be protected by a pressure relieving device or devices as

required.

16. Piping or other parts with a temperature in excess of 70˚C (158˚F) and which may be

accidentally touched by personnel in normal operation must be guarded or insulated. Other

high temperature piping must be clearly marked.

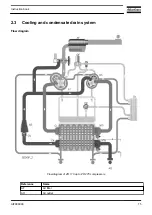

17. For water-cooled machines, the cooling water system installed outside the machine has to

be protected by a safety device with set pressure according to the maximum cooling water

inlet pressure.

18. If the ground is not level or can be subject to variable inclination, consult the manufacturer.

19. If the device is a dryer and no free extinguishing system is present in the air net close to the

dryer, safety valves must be installed in the vessels of the dryer.

Also consult following safety precautions:

Safety precautions during operation

Safety precautions during maintenance

These precautions apply to machinery processing or consuming air or inert gas.

Processing of any other gas requires additional safety precautions typical to the

application which are not included herein.

Some precautions are general and cover several machine types and equipment; hence

some statements may not apply to your machine.

1.4

Safety precautions during operation

All responsibility for any damage or injury resulting from neglecting these precautions, or

non observance of the normal caution and care required for installation, operation,

maintenance and repair, even if not expressly stated, will be disclaimed by the

manufacturer.

Precautions during operation

1. Never touch any piping or components of the machine during operation.

2. Use only the correct type and size of hose end fittings and connections. When blowing

through a hose or air line, ensure that the open end is held securely. A free end will whip

and may cause injury. Make sure that a hose is fully depressurized before disconnecting it.

3. Persons switching on remotely controlled machines shall take adequate precautions to

ensure that there is no one checking or working on the machine. To this end, a suitable

notice shall be affixed to the remote start equipment.

4. Never operate the machine when there is a possibility of taking in flammable or toxic fumes,

vapors or particles.

5. Never operate the machine below or in excess of its limit ratings.

Instruction book

AIF999999

7

Summary of Contents for ZR 200

Page 1: ...Instruction book AIF999999 ZR 200 ...

Page 2: ......

Page 61: ... CORRECT installation Instruction book AIF999999 59 ...

Page 108: ......

Page 109: ......