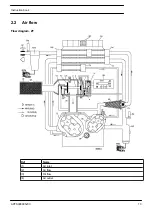

Explanation of arrows

Ref

Name

(1)

Air inlet

(2)

Air flow

(3)

Oil flow

(4)

Air outlet

Cooling system, ZT compressors

The compressors are provided with an air-cooled oil cooler (Co), intercooler (Ci), pre-aftercooler (Ca1) and

aftercooler (Ca2). An electric motor-driven fan (FN) generates the cooling air.

2.6

Energy recovery

General

The system recovers the major part of the compression heat. The percentage of shaft input power available

for recovery is between 80 and 95, depending on the operating conditions.

If an MD dryer is installed downstream of the compressor, this percentage is reduced to approx. 70 of the

shaft input instead of approx. 90, as part of the heat in the compressed air is used for regeneration in the drying

process.

A complete energy recovery system includes:

• Compressor with modified cooling system (ZR)

• A pump unit (PU) to transfer the recovered energy from the compressor cooling system to the heat

consumer (HC)

• The heat consumer (HC), i.e. the equipment to transfer the energy to the industrial process

Instruction book

APFS998935v00

19

Summary of Contents for ZT-55

Page 1: ...CustomDesign Oil free Air Project 998935 Customer AIR SEP USA ZT 55 Instruction book ...

Page 2: ......

Page 13: ...General view Rear view Instruction book APFS998935v00 11 ...

Page 25: ...Typical example Drive motor M1 Instruction book APFS998935v00 23 ...

Page 57: ...4 2 Installation proposals Installation proposal ZT Pack Instruction book APFS998935v00 55 ...

Page 88: ......

Page 89: ......