5

Operating instructions

5.1

Operation introduction

Warning

The operator must apply all relevant

.

Ambient conditions

for the limits with regard to the ambient conditions and altitude operation.

Moving/lifting

In order not to damage the frame, the compressor must be moved either by a lift truck or by using lifting

equipment as described below.

When moving the compressor with a lift truck, use the slots in the frame. Make sure that the forks protrude

from the other side of the frame. When moving the compressor with a lifting device, insert beams in the slots.

Make sure that the beams cannot slide and that they protrude from the frame equally. The chains must be held

parallel to the bodywork by chain spreaders in order not to damage the compressor. The lifting equipment

must be placed in such a way that the compressor is lifted perpendicularly. Lift gently and avoid twisting.

5.2

Initial start-up

Procedure

• Consult

• A sticker dealing in short with the operation instructions is delivered with the literature set. Affix the

sticker next to the control panel.

• A number of VCI (Volatile Corrosion Inhibitor) plates are provided inside the bodywork to protect the

compressor against corrosion. Remove the plates.

• The compressor and motor are secured to the frame immobilizing the vibration dampers during transport:

• At the motor side, loosen nut (1), remove bolts (2) and turn bracket (3) 90˚. Tighten nut (1).

Instruction book

62

APFS998935v00

Summary of Contents for ZT-55

Page 1: ...CustomDesign Oil free Air Project 998935 Customer AIR SEP USA ZT 55 Instruction book ...

Page 2: ......

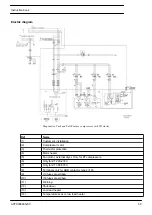

Page 13: ...General view Rear view Instruction book APFS998935v00 11 ...

Page 25: ...Typical example Drive motor M1 Instruction book APFS998935v00 23 ...

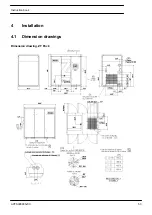

Page 57: ...4 2 Installation proposals Installation proposal ZT Pack Instruction book APFS998935v00 55 ...

Page 88: ......

Page 89: ......