20

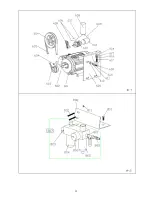

The FRL consists of the air filter (moisture separator), pressure regulator, and lubricator. The

filter is designed to prevent excessive amounts of water (normally found in compressed air) from

contaminating the moving parts of the tire changer. The pressure regulator helps to regulate

pressure and prevent the valves, cylinders and other moving parts from being damaged by

excessive air pressure. The lubricator provides oil to the pneumatic parts located inside the tire

changer.

SPECIFICATION

Maximum supply pressure

150psi

Minimum ambient operating temperature

5deg. C / 41deg. F

Recommended lubricating oil

50W SAE Oil (non-detergent)

Required regulator air pressure setting

110psi to 125psi

OPERATION AND MAINTENANCE

This is the pressure

regulator. Open (pull up)

the knob and turn to

adjust the air pressure.

Set air pressure at: 110

to125psi.

Close (Push down) the knob to

lock the regulator when the

correct air pressure is achieved.

pressure.

The air filter separates water

from the air as the air flows

into the machine. When the

water level reaches 50% of

the glass bowl, it is necessary

to drain the water by pulling

the locking ring and venting

the water.

Check the oil level in the lubricator at the

beginning of each work day. Keep the

reservoir filled with 50W SAE oil. Make

sure the air supply is disconnected from the

changer before removing the oil cap.

The oil indicator should be checked to make

sure that one drop of oil is injected into air

system every 3-4 times the Bead Breaker

Pedal is depressed. To regulate the rate of oil

injection, adjust the flow with the oil regulator

screw. IMPORTANT: Oil is needed in the air

supply system to properly maintain the seals

and working parts of the tire changer.