22

PROBLEM 1:

Turntable does not rotate.

Causes: Solutions:

No power to the machine.

Check the electric supply and reset breaker if needed.

Make sure the plug is in the socket. Do not use an

extension cord.

Motor belt broken or loose.

Adjust or replace the belt.

Switch or switch connections are bad.

Make sure the switch contacts are working properly.

Test switch.

Motor or motor connections are bad.

Check for loose wires in the motor. Test motor.

Motor pedal broken or loose object underneath

prevents full movement.

Clean under pedal. Repair or replace reverse pedal

assembly.

PROBLEM 2:

Turntable vibrates while mounting/removing tire.

Causes: Solutions:

Belt loose or glide fasteners are loose.

Adjust belt tension and tighten all fasteners.

PROBLEM 3:

Jaws clamping cylinders slow to open/close.

Causes: Solutions:

Silencer (air muffler) is clogged.

Clean or replace silencer (air muffler).

PROBLEM 4:

Clamping cylinders jaws do not lock the wheel rim correctly.

Causes: Solutions:

Jaws worn.

Replace jaws.

Worn air cylinder

Replace cylinder or rebuild cylinder with gaskets.

Leaking air fittings

Correct air leak, replace fitting if necessary.

PROBLEM 5:

Mounting Head touches the wheel rim during tire mounting/demounting

process.

Causes: Solutions:

Locking slide for hex shaft is incorrectly adjusted or

defective.

Adjust or replace locking slide.

Locking slide for hex shaft screw is loose.

Tighten screw. See section 10 for head adjustment.

PROBLEM 6:

Bead Breaker Pedal and Jaw Clamp Pedal do not return to original position.

Causes: Solutions:

Pedal return spring is broken.

Replace pedal return spring.

PROBLEM 7:

Bead breaker not operating properly.

Causes: Solutions:

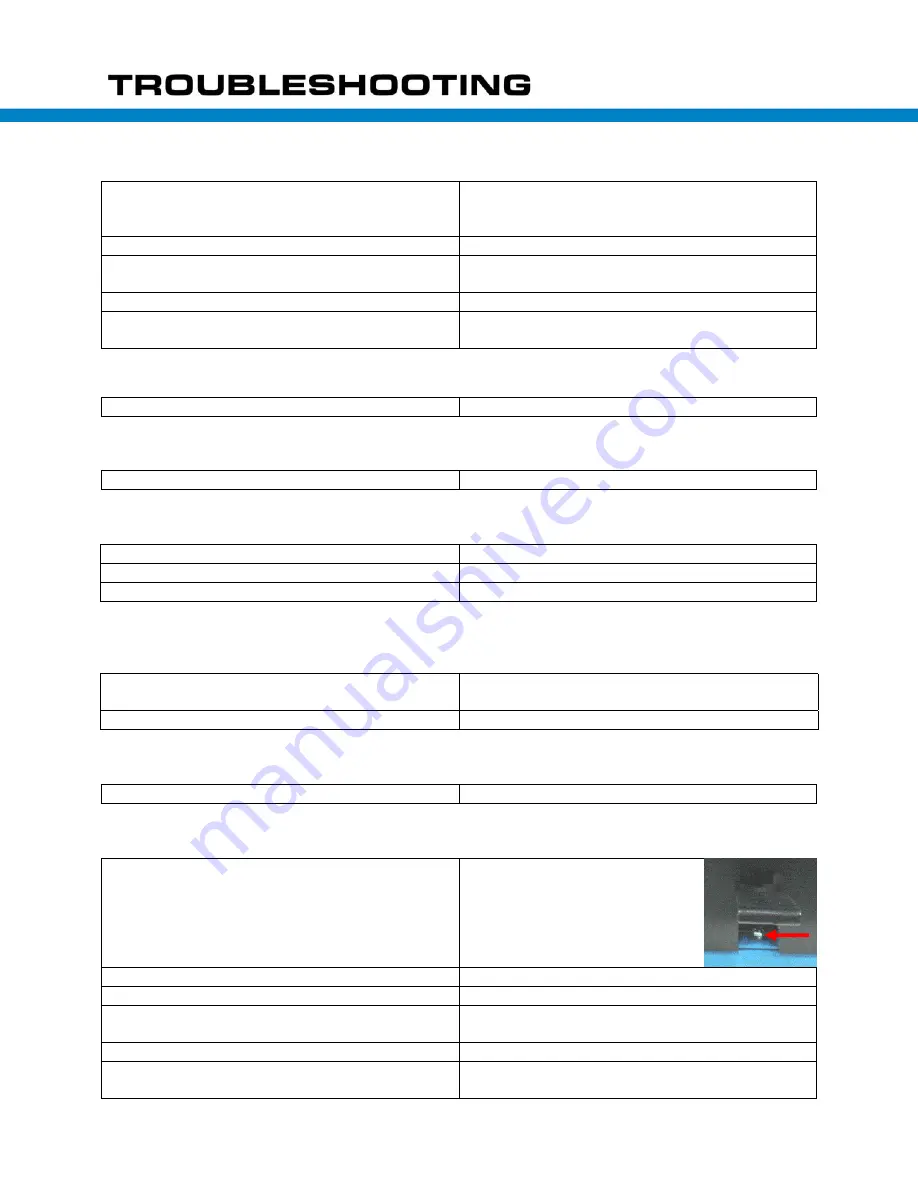

The pedal stop bolt is not adjusted correctly.

Adjust the height of the

pedal stop bolt. (The stop bolt

is under the bead breaker pedal.

See photo above.

5 port valve muffler (silencer) is clogged.

Clean or replace 5 port valve mufflers (silencers).

5 port valve O-rings are broken or worn.

Replace the 5 port valve O-rings.

Bead breaker cylinder piston V-seal or rod O-ring is

damaged.

Replace bead breaker cylinder piston V-seal or the

breaker cylinder assembly.

Insufficient air supply to the changer.

Make sure the inlet air pressure is sufficient.

Lack of lubrication.

Fill the lubricator; adjust the lubricator as explained

in chapter 7.