3

JUNCTION BOX MOUNTING

OPTIONS

Secure the outlet box directly to the building

structure. Use appropriate fasteners and

building materials. The outlet box and its

support must be able to fully support the

moving weight of the fan (at least 45 lbs.).

Use a UL Listed metal outlet box. Do not use

a plastic outlet box.

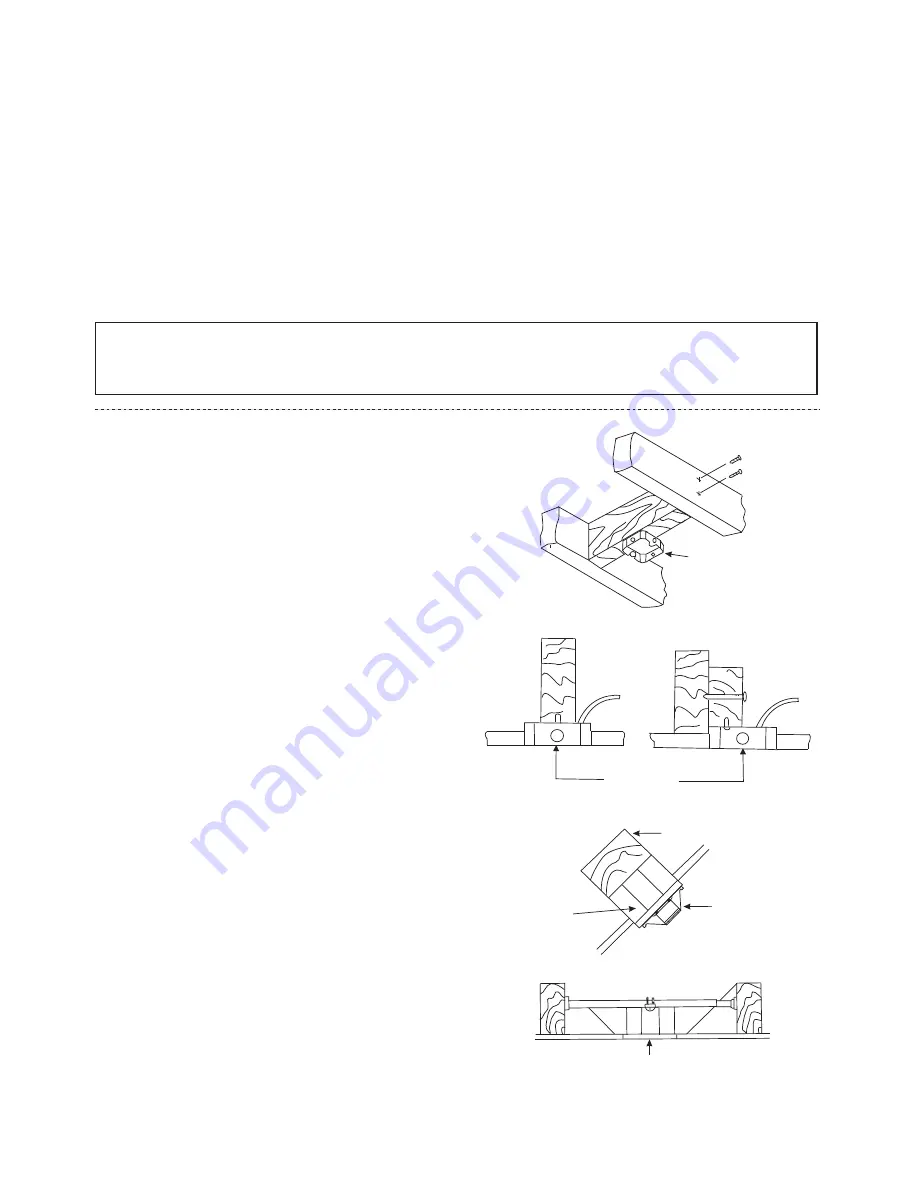

Figures 1, 2 and 3 are examples of different

ways to mount the outlet box.

Note:

You may need a longer down rod to

maintain proper blade clearance when

installing on a steep, sloped ceiling. (Fig. 3)

To hang your fan where there is an existing

fixture but no ceiling joist, you may need an

installation hanger bar as shown in Fig. 4.

Figure 1

Outlet box

Outlet box

Figure 2

Provide strong

support

Recessed

outlet box

Figure 3

Ceiling

hanger

bracket

ANGLED CEILING

MAXIMUM 24° ANGLE

11. To reduce the risk of personal injury, install the supplementary mounting means and use

only the hardware provided with the fan.

12.

Warning:

TO REDUCE THE RISKS OF FIRE, ELECTRIC SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have any questions,

contact the manufacturer.

B. Before installing, servicing or cleaning unit, switch power off at service panel and lock

service panel to prevent power from being switched on accidentally.

13.

Warning:

To reduce the risk of fire, electrical shock or personal injury, mount to outlet box

marked acceptable for fan support and use screws provided with outlet box.

Outlet box

Figure 4

ATTENTION:

Fan includes a 190W limiter to comply with the department of energy 2009

regulation. Lamping this product over 190w will cause this fan to not light. Please use bulbs

with a total wattage under the 190W regulation.