5

Figure 8

10 A. Metal Blades and Decorative Cages:

If

your fan is one with metal blades and

decorative cages, remove protective plastic

sleeve from the motor shafts, and then attach

the metal blades and cages. Bolts to attach

cages are in the hardware pack, 'i'. The Atlas

medallion should be oriented correctly. Handle

your blades carefully otherwise you will bend

the blade irons and cause your fan to vibrate

when in use. Caution: The set screw in the

blade hub must be counter-sunk into the

bore-hole on the flattened side of the motor

shaft - or else the blades may disengage from

the motor shaft during operation.

10 B. Metal Blades and Safety Cages:

If your fan

is one with metal blades and safety cages,

remove protective plastic sleeve from the motor

shafts, then and attach the back side of the

safety cage. Bolts to attach cages are in the

hardware pack, 'i'. Next, attach the blade.

Handle your blades carefully otherwise you will

bend the blade irons and cause your fan to

vibrate when in use. Finally attach the front side

of the cage with Atlas medallion oriented

correctly. Caution: The set screw in the blade

hub must be counter-sunk into the bore-hole on

the flattened side of the motor shaft - or else

the blades may disengage from the motor shaft

during operation.

10 C. Wooden Blades:

If your fan is one with

wooden blades, attach your blades as the last

step in the assembly process. Do not attach

them now.

Attach them in step No.: 13.

Handle your blades carefully otherwise you will

bend the blade irons and cause your fan to

vibrate when in use.

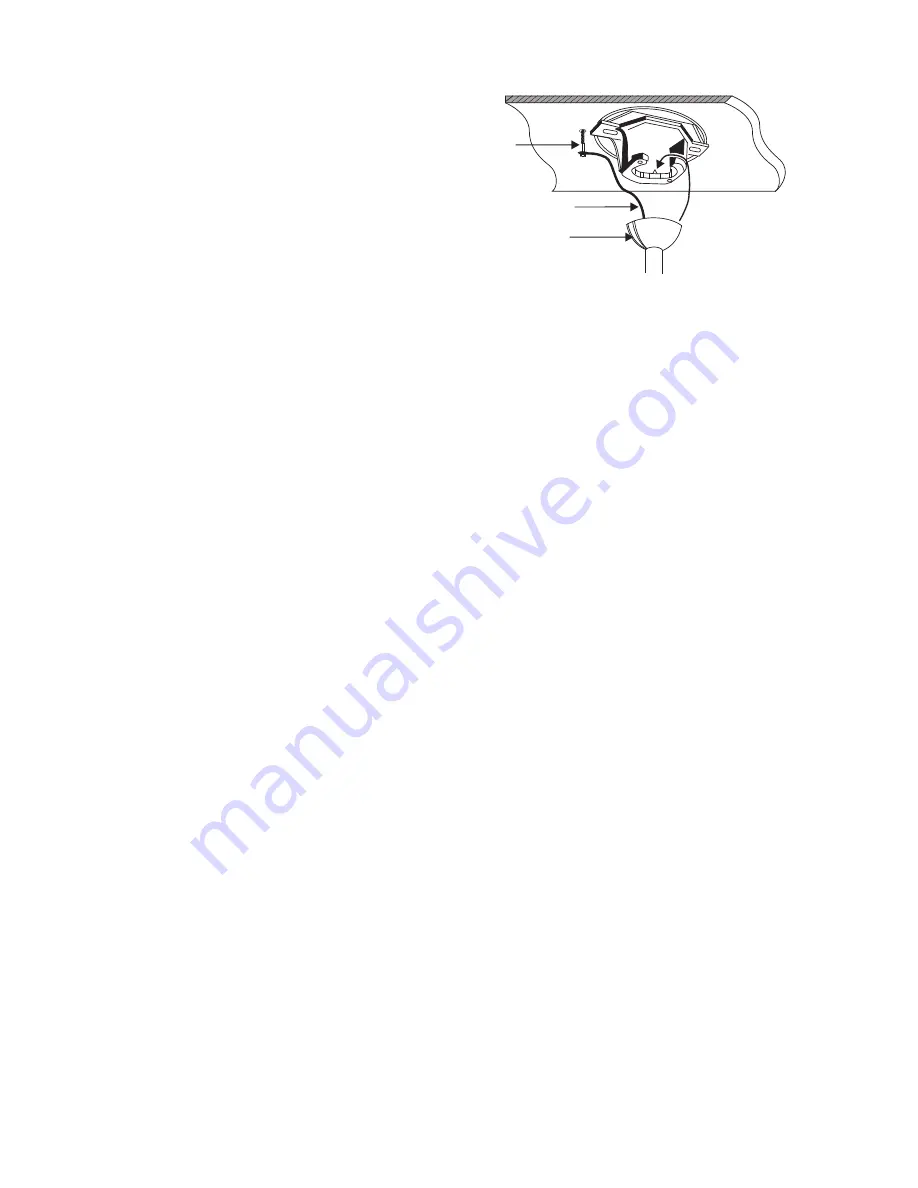

11. Now lift the motor assembly into position and

place the hanger ball into the hanger bracket.

Rotate down rod until the "Check Tab" has

dropped into the "Registration Slot" and the

down rod and ball assembly seat firmly. The

down rod and ball assembly should not rotate if

this is done correctly.

12. An additional safety support is provided to

prevent the fan from falling. Secure the safety

cable to the ceiling joist with screw and washer.

(Fig. 8)

13. Remove protective plastic sleeve from the

motor shaft and attach your wooden blades.

Ignore this step if you have metal blades, as

they should already have been installed. Make

sure that the set screw in the blade hub is

counter-sunk into the bore-hole in the motor

shaft - or else the blades may disengage from

the motor shaft during operation.

Registration

slot

Screw

Safety cable