9 |

P a g e

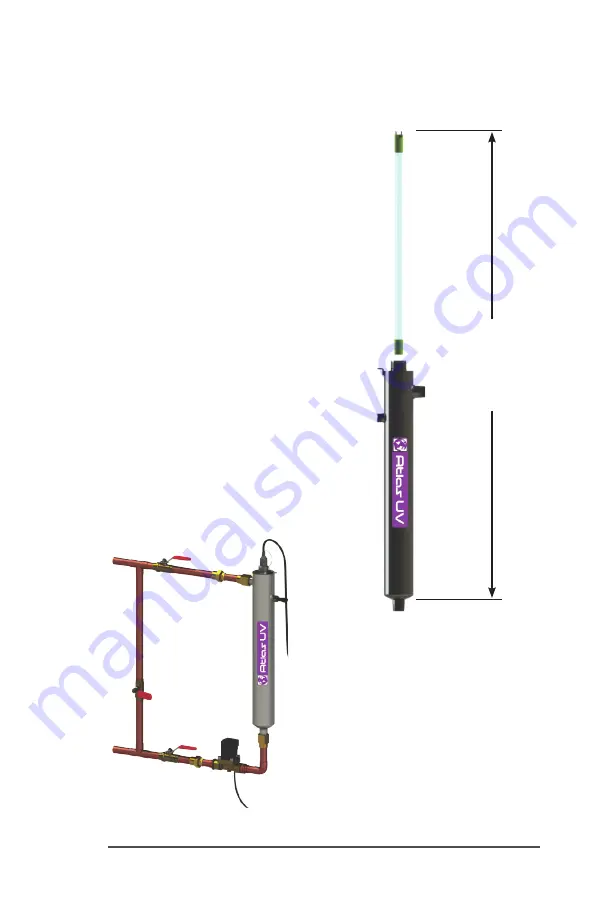

To facilitate lamp removal, ensure there is enough space at the lamp connector end to safely

remove the UV lamp and/or quartz sleeve (See Figure 2). The controller will require a ground

fault circuit interrupter (GFCI or GFI) outlet and should be mounted beside or above the reactor.

PLEASE NOTE: All Atlas UV disinfection systems are intended for indoor use only as they should

not be exposed to the elements.

Installation

Step 1: The reactor can be installed either horizontally or

vertically using the clamps provided. Vertical installation is

the preferred method with the inlet at the bottom (lamp

connection at the top) as it allows any air that may be in the

lines to be easily purged from the system.

Step 2: The use of a by-pass assembly is recommended as

it will allow you to isolate the UV reactor. This will allow for

easier access in case maintenance is required (See Figure 3).

Step 3: Use the supplied fasteners to mount the UV reac-

tor to wood or drywall. If mounting to an alternate material

you will need to purchase the proper corresponding fasten-

ers.

Step 4: For water supplies where the maximum flow rate

is unknown, a flow restrictor is recommended so that the

rated flow of your particular Atlas system is not exceeded.

The flow restrictor should be installed on the inlet port of

the reactor.

Step 5: It is recommended to have a licensed plumber

connect the UV reactor to the water supply and may be a

requirement depending on where you are located.

Figure 3. By-pass assembly

Figure 2. Lamp Removal

Spacing

leave at least

an additonal

reactor length

to facilitate

lamp and

sleeve removal

Note: Installation of your

Atlas disinfection systems

shall comply with applicable

provincial/state & local regu-

lations.

Summary of Contents for H Series

Page 26: ...2 6 P a g e ...

Page 27: ...2 7 P a g e ...

Page 28: ...www atlasuv co uk PN 910086 Version Date 06 2021 ...