25

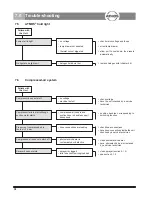

5.1

General information on cleaning and

disinfection

Set main switch to OFF prior to cleaning and

disinfection!

The described measures for cleaning do not re

place the respective precautions for operating the

unit !

For disinfection, you may use all surface and instrument

disinfectants listed on page 26.

Always observe the concentration specifi cations and

instructions by the respective manufacturer !

Do not use

• Disinfectants containing concentrated organic or an-

organic acids or bases, since these may cause

corrosion damages;

• Disinfectants containing chloramides, phenol deri-

vatives or anionic tensides, since these may cause

stress cracks in the material used for the housing of

the unit.

5.1.3

Secretion canister (without autom.

secretion canister evacuation),

bacterial fi lter and suction hose

At the end of every working-day,

following parts must be

cleaned and disinfected:

Secretion canister with lid system and bacterial fi lter:

•

Detach all hose connections carefully on the lid system

and take secretion canister out carefully to prevent spills and

contamination of the area. Dispose of secretions

properly.

• Grip lid system fi rmly, open lid of fi lter housing by turning

in anti-clockwise direction.

• For systems with bacterial fi lter plates or integrated

bacterial fi lter:

Remove fi lter and dispose of it.

• With external bacterial fi lter:

To open the bacterial fi lter cover please turn it. Remove

fi lter and dispose of it.

• After cleaning a new filter must be inserted (with

bacterial fi lter plate: smooth side down).

See chapter 6.1.

• The bacterial fi lter is a disposable and must be disposed

of. The bacterial fi lter must be exchanged at least once

a day.

Suction system and hose attachment:

• After every use, rinse out the suction system by

drawing in a small amount of irrigating fluid (e.g.

ATMOS Special Cleanser 080.0005.0).

Keeps the hoses from becoming sticky or

clogged.

Suction capacity is limited by the 1.25 l secretion

canister. Therefore, do not use more than 1 l rinsing

liquid and subsequently evacuate the canister.

Replace The fi lter.

5.1.2

Cleaning "application parts"

"Application parts" comprise:

All single components or assemblies which come into

contact with the patient and might get contaminated:

•

secretion canister,

•

secretion hose,

•

nozzles of medicament sprayers,

•

Politzer olives and adapters.

All application parts may disinfected with instrument

disinfectants (see page 26).

All application parts which are exposed to direct

contact with the patient during treatment are to be

exchanged or cleaned immediately for hygienic

reasons.

5.1.1 Cleaning the unit surface

The surfaces of the ATMOS

®

C 31

are resistant against all

listed surface disinfectants.

Wipe the unit surface with a cloth moistened with a cleaning

or disinfecting solution.

Wipe dry the device surface, the surface edges may not

be wet for a longer period.

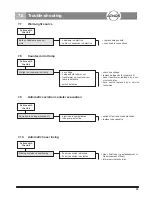

5.1.4

Secretion canister and electrodes

(automatic evacuation of

secretion canister)

The secretion canister should be removed and cleaned once

every week.

•

During the cleaning of the canister the cover has to be

pulled off and rinsed thoroughly under running water.

Use the disinfectants mentioned in chapter 5.4 for

disinfection. Before the canister is assembled again, the

electrodes in the cover should be cleaned using a wet

cloth.

Mistake in polarity not possible!

5.0 Cleaning