Summary of Contents for Multi Mk2

Page 1: ...APPENDIX ATMOS MULTI Mk2 version 2004 Appendix Page 1 ...

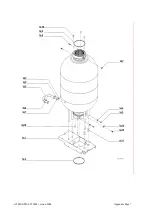

Page 5: ...ATMOS MULTI Mk2 version 2004 Appendix Page 5 ...

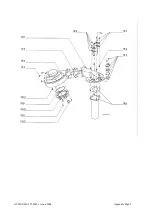

Page 6: ...ATMOS MULTI Mk2 version 2004 Appendix Page 6 ...

Page 7: ...ATMOS MULTI Mk2 version 2004 Appendix Page 7 ...

Page 8: ...ATMOS MULTI Mk2 version 2004 Appendix Page 8 ...