SAFETY AND MAINTENANCE MANUAL

1NO0024UK-09

71

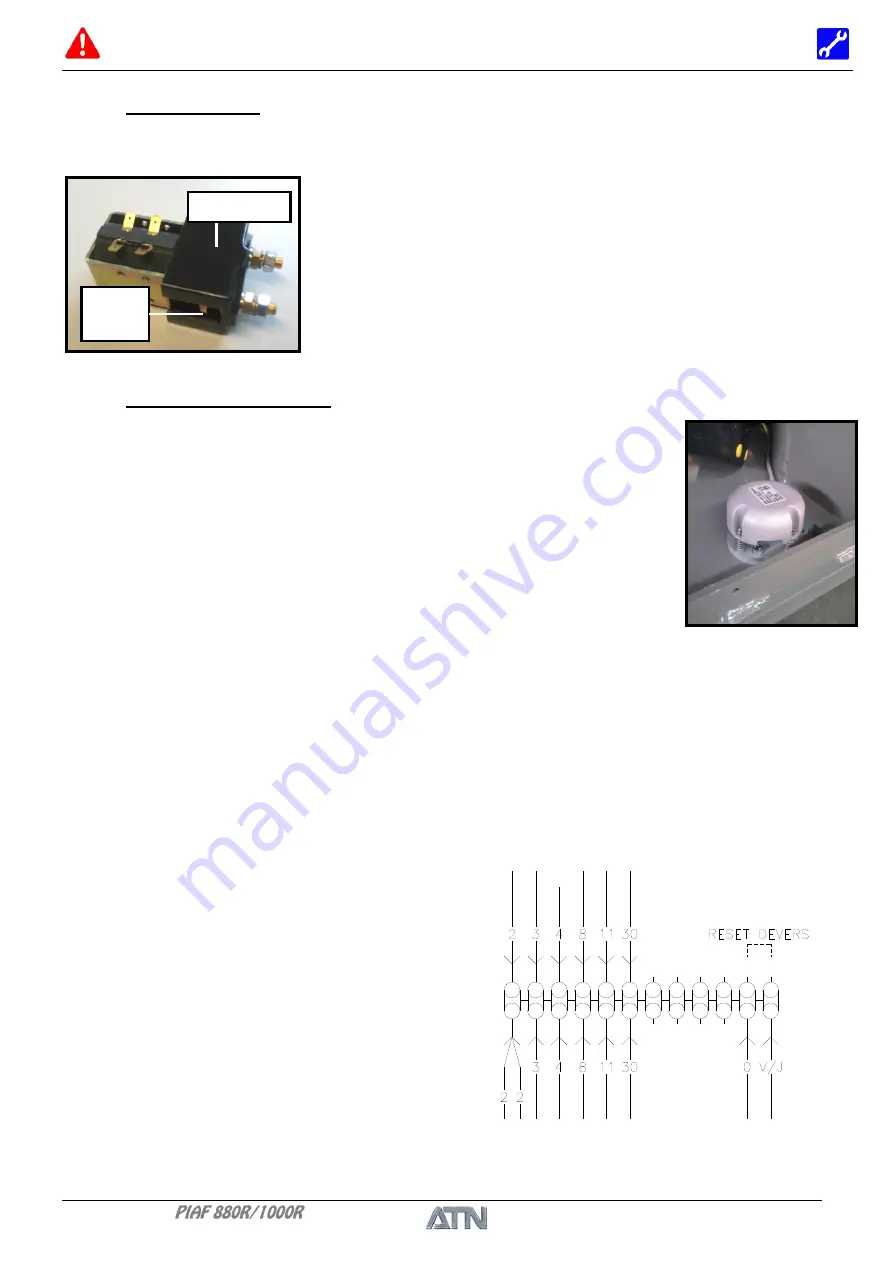

Mobile

part

Partie fixe

3.5. CONTACTOR

GENERALITIES

The power contactor is used to run the electric motor. It needs the

same upkeep as the motor. Regularly, it is necessary to clean by

blowing around the contacts. Check the state of surface of the

fixed and mobile parts of the contacts. Replace if necessary.

3.6. INCLINE DETECTOR

CONTROL PROCEDURE OF THE INCLINE DETECTOR

- place the machine on a slope of more than 2°.

- the buzzer of the alarm situated in the lower electrical box must be heard.

- the incline indicator situated on the upper box must be lit.

- the machine must be in 2

nd

speed.

- this means that the running is correct.

- NB -

This is just a control of the sound running of the incline detector - the adjustment must be

made on a test bench.

ADJUSTMENT OF THE ZERO REFERENCE POINT

When the rack is inclined at 2° to horizontal, the detector triggers the

buzzer and lights up the indicator light corresponding to the incline

situated on the upper control box. Moreover, the machine changes

automatically into second speed. The triggering of these alarm signals

indicates that the aerial work platform is reaching its stability limits.

It is therefore necessary to check this detector every day before any use

of the machine.

The system is supplied with standard

adjustment

and

configuration.

After

mechanical installation, it is important to

adjust the zero point, in other words to give

the system the new zero reference point.

Use a wire to bridge the 2 terminals (RESET

INCLINE), maintain the bridging until the

end of the blinking of the green LED

situated under the detector.

Fixed part

Summary of Contents for PIAF 1000R

Page 2: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 2 DISTRIBUTOR STAMP...

Page 8: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 8...

Page 11: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 11 Chapter I USE AND SAFETY...

Page 12: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 12...

Page 16: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 16...

Page 22: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 22...

Page 34: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 34...

Page 36: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 36...

Page 37: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 37 Chapter II MAINTENANCE...

Page 38: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 38...

Page 77: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 77 3 13 ELECTRICAL DIAGRAM Diagram ref 1EL0023 01...

Page 78: ...SAFETY AND MAINTENANCE MANUAL 1NO0024UK 09 78 NOTES...