SAFETY AND MAINTENANCE MANUAL

1NO0055UK-00

PIAF 10

E

50

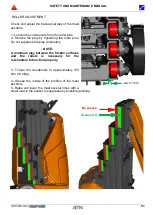

SURVEILLANCE OF THE PROTECTION

Visual examination can determine the integrity of the protection seals:

- absence of excessive tensions and tears.

- correct position.

- wear of the floating lip.

If necessary, replace the seal. After lubrication, remove the used greased and check for absence

of pollution like sand, brush dust, metal particles, etc…

SURVEILLANCE OF THE FIXATION

The fasteners for the turntable bearings work essentially in fatigue, it is therefore particularly

important to check that the pre charge level required for the nuts and bolts is always kept (Bolt H

M16x90 8.8 ZI).

The fasteners must be re-torqued after the first 2 to 4 months of operation, then each year

systematically.

If bolts are found loose, an expertise must be done. They cannot just be re-torqued, they must be

removed completely, then brushed and torqued again with High-strength Threadlock. Certain

regulations require replacement of all nuts and bolts every 7 years or every 14000 operating hours.

SURVEILLANCE OF THE ROTATION

During cleaning prior to greasing the teeth :

- Check carefully for the absence of foreign bodies in the teeth, turntable and sprocket.

- Check the evenness of the longitudinal range of the sprocket over the width of the turntable teeth

and correct the pin alignment if necessary.

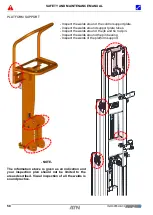

1.2. MAST SECTIONS

1.2.1 FIXED MAST SECTION AND ITS CYLINDER

The machine is made of a mast section fixed on the chassis and of four mobile mast sections. The

assembly is a telescopic mast.

The mast cylinder is secured on the fixed mast section and the first mobile mast section. The link

between the other three is accomplished through lifting chains.

Other than lubrication of the fixed mast section, no particular maintenance is required. It is

however necessary to control the cylinder rod for the following:

- Rust.

- Scratches that would result in worn seals and leaks.

- Leaks: it is necessary to replace the seals.

1.2.2 MOBILE MAST SECTIONS

The four mobile mast sections require for only maintenance a light lubrication on the friction

surfaces between the roller ends and the mast sections without going over on the rolling surfaces.

It is important to keep clean the inside of the mast sections.

Summary of Contents for PIAF 10E 2018

Page 2: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 2 DISTRIBUTOR STAMP...

Page 8: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 8...

Page 10: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 10...

Page 13: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 13 Chapter I OPERATION AND SAFETY...

Page 14: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 14...

Page 18: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 18...

Page 24: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 24...

Page 42: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 42...

Page 43: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 43 Chapter II MAINTENANCE...

Page 44: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 44...

Page 66: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 66 2 3 HYDRAULIC SCHEMATIC...

Page 78: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 78 3 10 ELECTRIC SCHEMATIC...

Page 79: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 79...

Page 80: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 80 NOTES...

Page 81: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 81 NOTES...