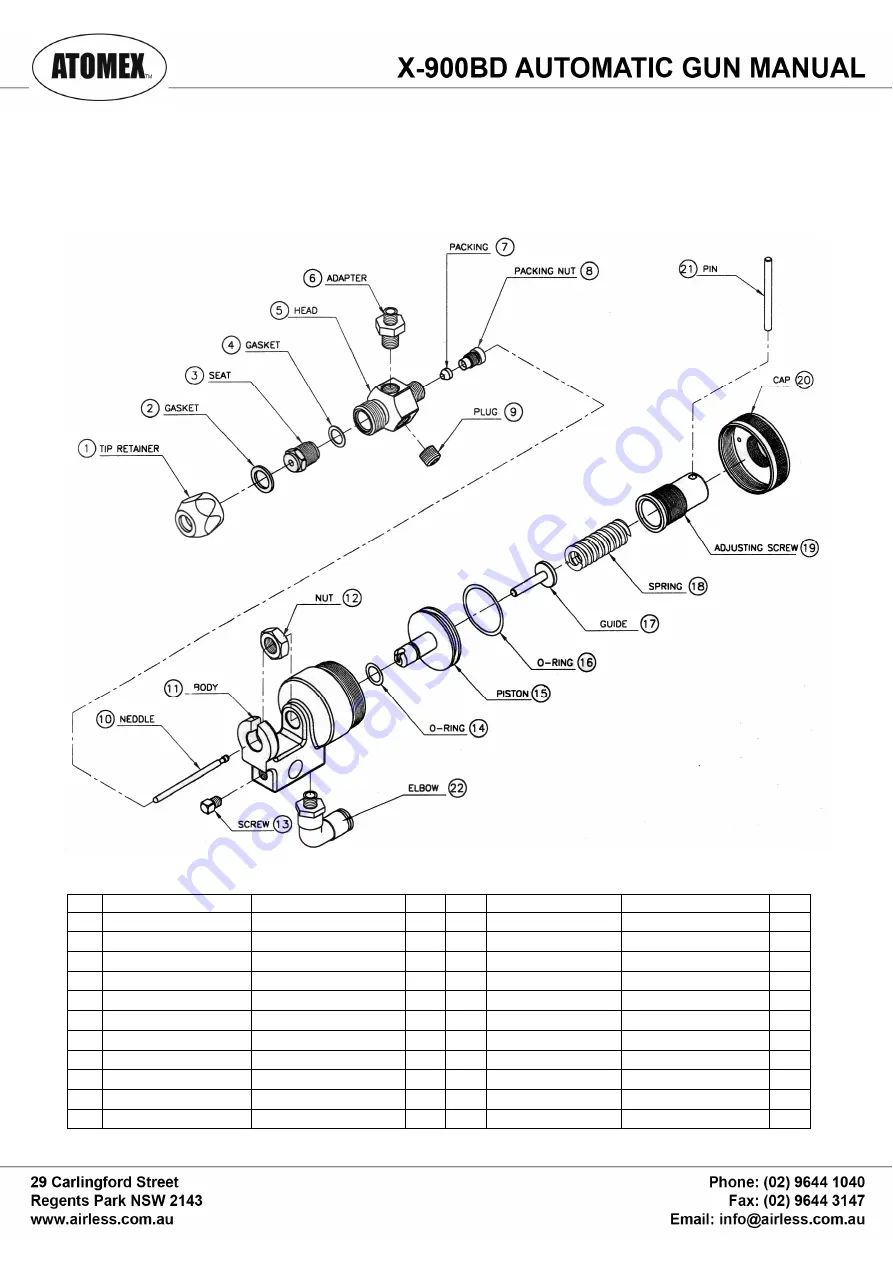

X-900BD PART DRAWING

NO. PART NO.

DESCRIPTION

QTY NO. PART NO.

DESCRIPTION

QTY

1

AX/02-900-001

Tip retainer

1

12

AX/02-900-012

Nut

1

2

AX/02-900-002

Gasket

1

13

AX/02-900-013

Screw

1

3

AX/02-900-003

Seat

1

14

AX/02-900-014

O-Ring

1

4

AX/02-900-004

Gasket

1

15

AX/02-900-015

Piston

1

5

AX/02-900-005

Head

1

16

AX/02-900-016

O-Ring

1

6

AX/02-900-006

Adapter

1

17

AX/02-900-017

Guide

1

7

AX/02-900-007

Packing

1

18

AX/02-900-018

Spring

1

8

AX/02-900-008

Packing nut

1

19

AX/02-900-019

Adjusting screw

1

9

AX/02-900-009

Plug

1

20

AX/02-900-020

Cap

1

10 AX/02-900-010

Needle

1

21

AX/02-900-021

Pin

1

11 AX/02-900-011

Body

1

22

AX/02-900-022

Elbow

1