INSTALLATION MANUAL

•

Check the tightness of the spray tip retaining nut.

•

Before each day’s operation, lubricate the exposed portions of the needle and the piston with a

lubricant compatible with the fluid to be sprayed.

•

Use a fluid filter to remove particles and sediment that could clog the tip.

•

Set the actuating mechanism (timer) so that the gun will start spraying before meeting the work

piece and stop spraying just after the work piece has passed.

•

Set the actuating air to at least 50psi (3bar) and start the pump.

•

The spray tip orifice size and angle determines coverage and pattern. Don’t try to get more

coverage by increasing the pump pressure – use a larger tip instead.

•

In a circulating system, adjust the back pressure valve to provide constant system back

pressure for all guns while maintaining proper pressure for fluid circulation. Refer to the

installation manual.

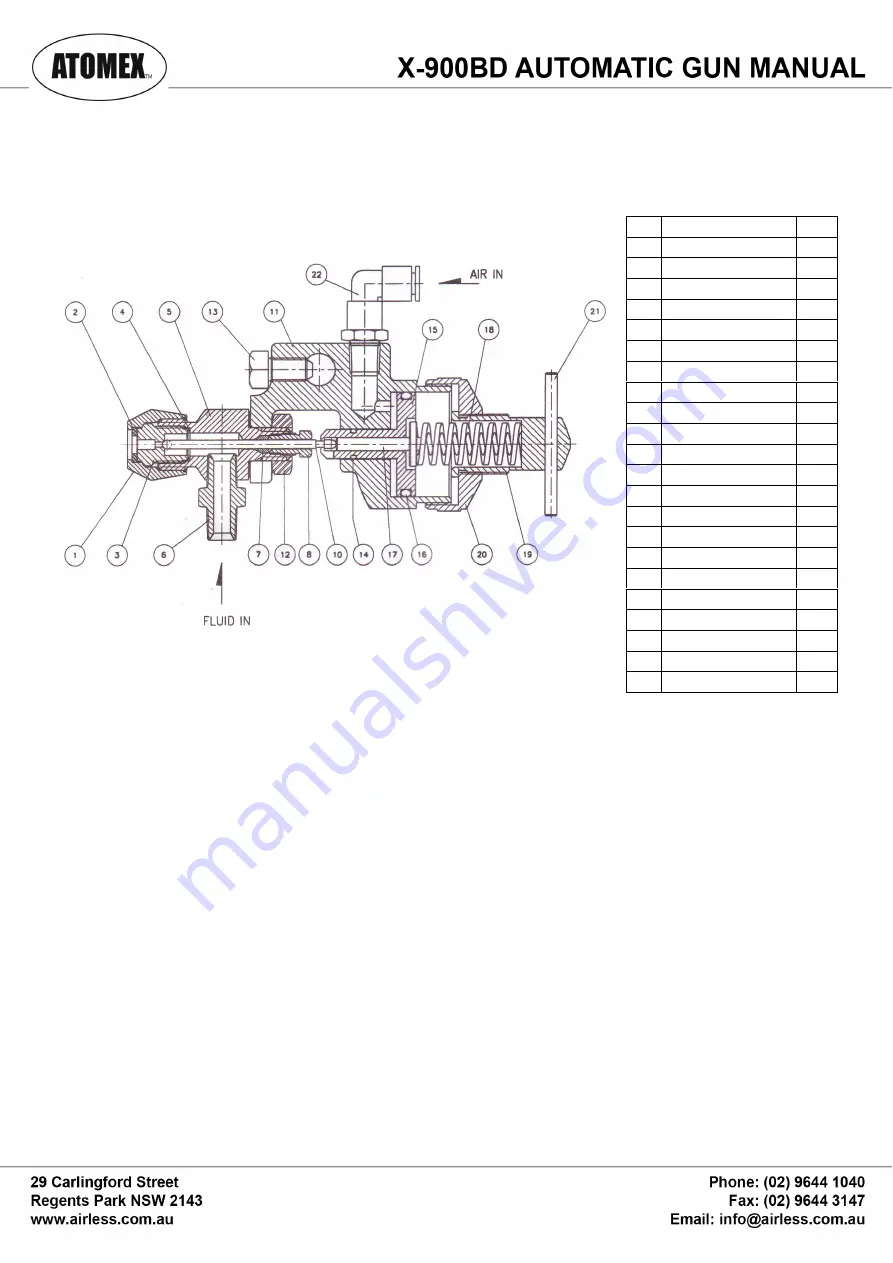

NO. DESC.

QTY

1

Tip retainer

1

2

Gasket

1

3

Seat

1

4

Adapter

1

5

Head

1

6

Adapter

1

7

Packing

1

8

Packing nut

1

9

Plug

1

10

Needle

1

11

Body

1

12

Nut

1

13

Screw

1

14

O-Ring

1

15

Piston

1

16

O-Ring

1

17

Guide

1

18

Spring

1

19

Adjusting screw

1

20

Cap

1

21

Pin

1

22

Elbow

1