5

MANU3610-01

INSTALLATION

The Series 3610 is an environmentally sealed device; therefore all cables supporting the peripheral devices,

communications and power sources must be inserted through the appropriate watertight connectors. Observance to

this requirement will ensure watertight integrity and protection against external elements.

Mounting

: The case and hinged front cover are made from durable fiberglass polyester. The sealed terminal

comes with four plastic mounting ears. These ears should be secured to the bottom underside of the enclosure

and extend out from the sides to allow for wall mounting. A special mounting plate is available if an

integrated reader is purchased.

Cabling

: A twisted pair or category 5 style

round

cable is required. Select the appropriate seal tight

connectors and remove the nylon plugs to accommodate data transmission and 12VDC power pack cable

assemblies. The cable is passed through the seal tight connector that is then tightened down over the cable.

One seal tight connector per cable is allotted (see diagram below). The supplied rubber tubing should be slid

over any cable if the seal tight connector does not clamp the cable securely. This should be done before

tightening the connector.

Power

: When terminal power is being supplied locally, insure that a conventional 110VAC-wall outlet,

220VAC in Europe and other areas, (check local electrical code requirements) is available to accept the Series

3610 power pack assembly. The outlet should be no further than four (4) feet from the terminal.

Base

: Locate a flat wall surface to accommodate the Series 3610. Typical mounting height is forty-eight

inches from floor to the terminal display (Compliant to the Americans with Disabilities Act). Observe OSHA

and/or local safety codes when operating tools during all phases of installation. Attach the four terminal

mounting ears (or mounting plate) to a flat wall surface.

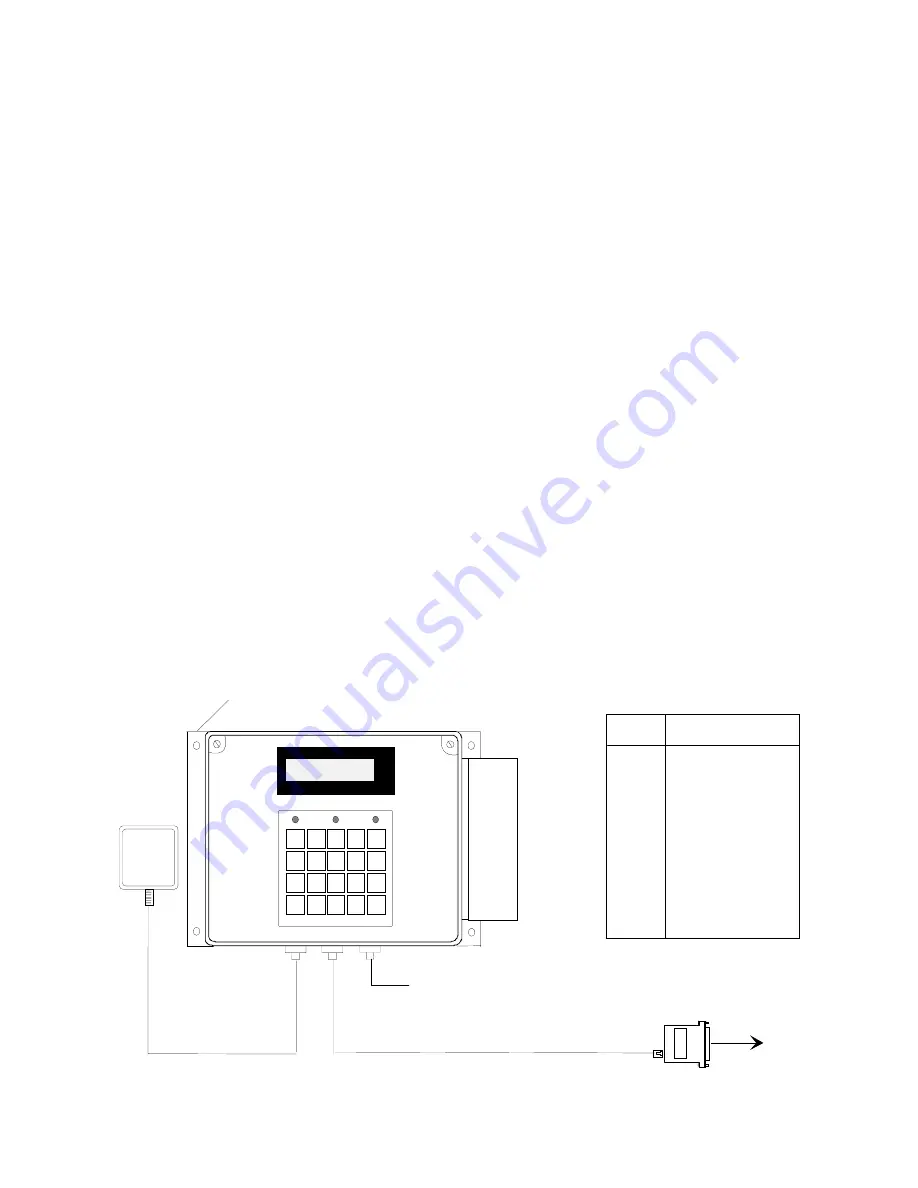

For RS232 communication applications, one end of the communication cable terminates into the Series 3610

communication port while the other terminates into the host computer’s serial port via an ATS RS232

Communication Adapter. For remote powering, a Network Junction Box or Network Junction Box Jr. could be

used.

RS232 INSTALLATION

COMM ADAPTER

DB25-RJ45 W/PWR

TO HOST

ATS

POWER

SUPPLY

ACCU-TIME SYSTEMS

ELLINGTON, CT

LOW

POWER

INVALID

VALID

1 2

3

4 5

6

7 8 9

0

CLEAR

ENTER

F1

F2

F3

F4

F5

F6

F7

F8

External

Reader

Mounting

NOTE: Pinouts are referenced to the terminal

Pin # Description

1

2

3

4

5

6

7

8

Earth Ground

Receive

Transmit

N/C

N/C

Ground

+VDC

Ground

Reader Port

Mounting Plate

Assembly