1. GENERAL INFORMATION

1.1 FUNCTIONAL DESCRIPTION

The desiccant air dryer is a pressure appliance designed to remove humidity from

compressed air.

It is made of two identical pressure vessels, which are filled with:

-aluminum oxide Al2O3 (for HGO models)

-molecular sieve

+

aluminum oxide (for HGL models)

Alumina is an adsorption-drying agent, which binds humidity.

Molecular sieve is an adsorption agent that binds to smaller molecules of water

vapour

which alumina can’t.

The columns are connected with two aluminium blocks. On the lower block are

located four valves and one silencer.

The valves force the air into the columns in order to dry the air in one vessel and

regenerate the alumina in the second one.

1.2 USE OF THE MACHINE IN SAFE CONDITIONS

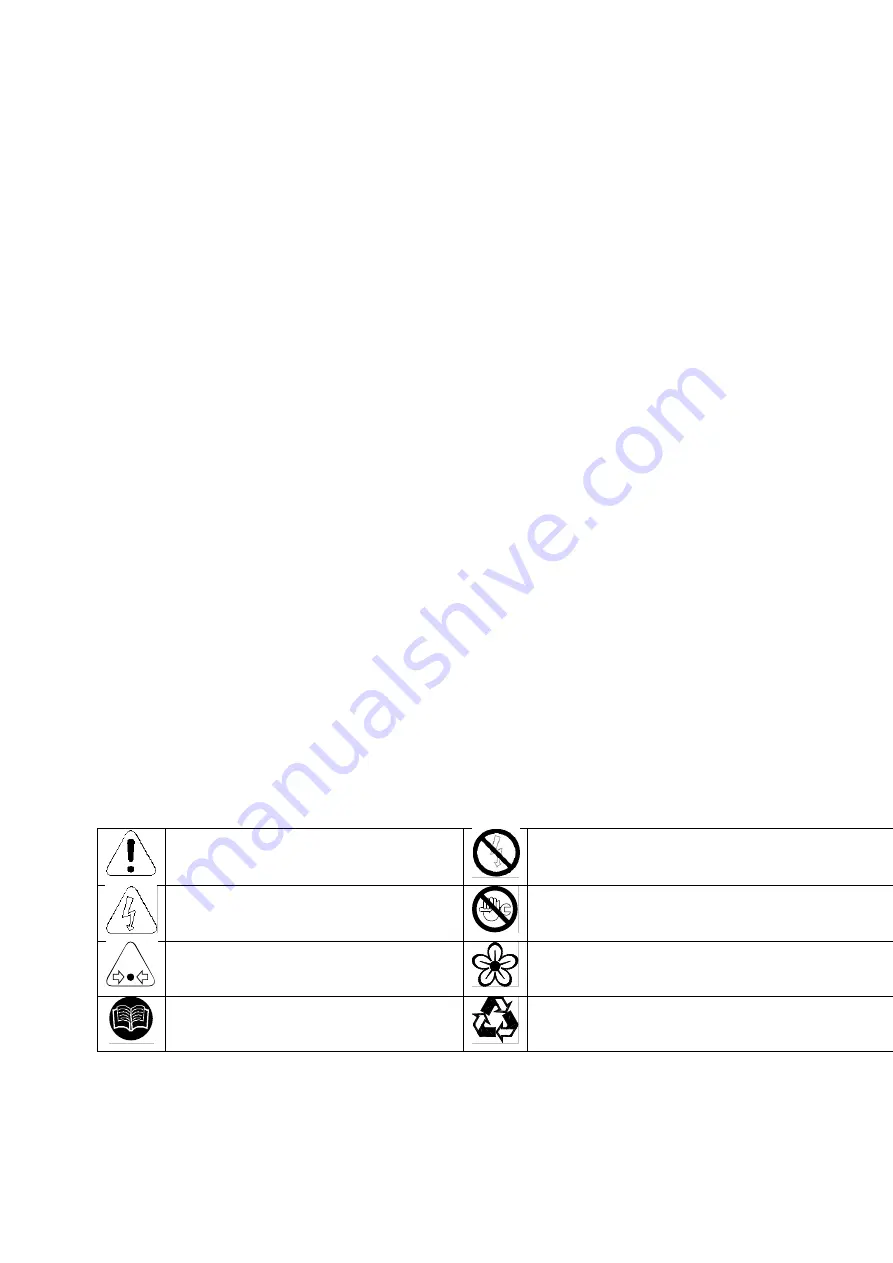

Symbols applied on the dryer and manual

General warning

Do not touch electrical hazard

Danger - high voltage, electrical

current

Prohibition of maintenance to unqualified

personnel

Danger point

Environmental requirements

Mandatory consulting the manual

Recyclable materials

This system has been designed and manufactured in compliance with the European

safety directive in force, therefore any installation, use and maintenance operations

must be performed respecting the instructions contained in this manual.

Summary of Contents for HGL 120

Page 17: ...B Schemat przep ywu powietrza...

Page 18: ...C Wymiary osuszacza...

Page 20: ...D Schemat elektryczny...

Page 21: ...E Widok rozstrzelony...

Page 23: ...DESICCANT DRYER Instruction and Maintenance Manual...

Page 24: ...HGO 40 160 HGL 40 160...

Page 27: ...B Flow diagram C Dryer dimensions D Wiring diagram E Exploded view F Suggested spares...

Page 41: ...LIST OF ATTACHMENTS...

Page 44: ...A C IN L E T O U T L E T IN L E T E B F G D MODEL 40 80 120 160 INLET OUTLET INLET...

Page 46: ...D WIRING DIAGRAM C CONTROLLER EMV 1 EMV 2 EMV 3 EMV 4 EMV ELECTROMAGNETIC VALVE...