0=TIMED SEQUENCE CONTROL

1=DEW POINT CONTROL SENSOR TYPE 1

2=DEW POINT CONTROL SENSOR TYPE 2

3=REMOTE CONTROL

P5

0

0

1

1

Type of REMOTE CONTROL.

0=normally open contact

1=normally closed contact

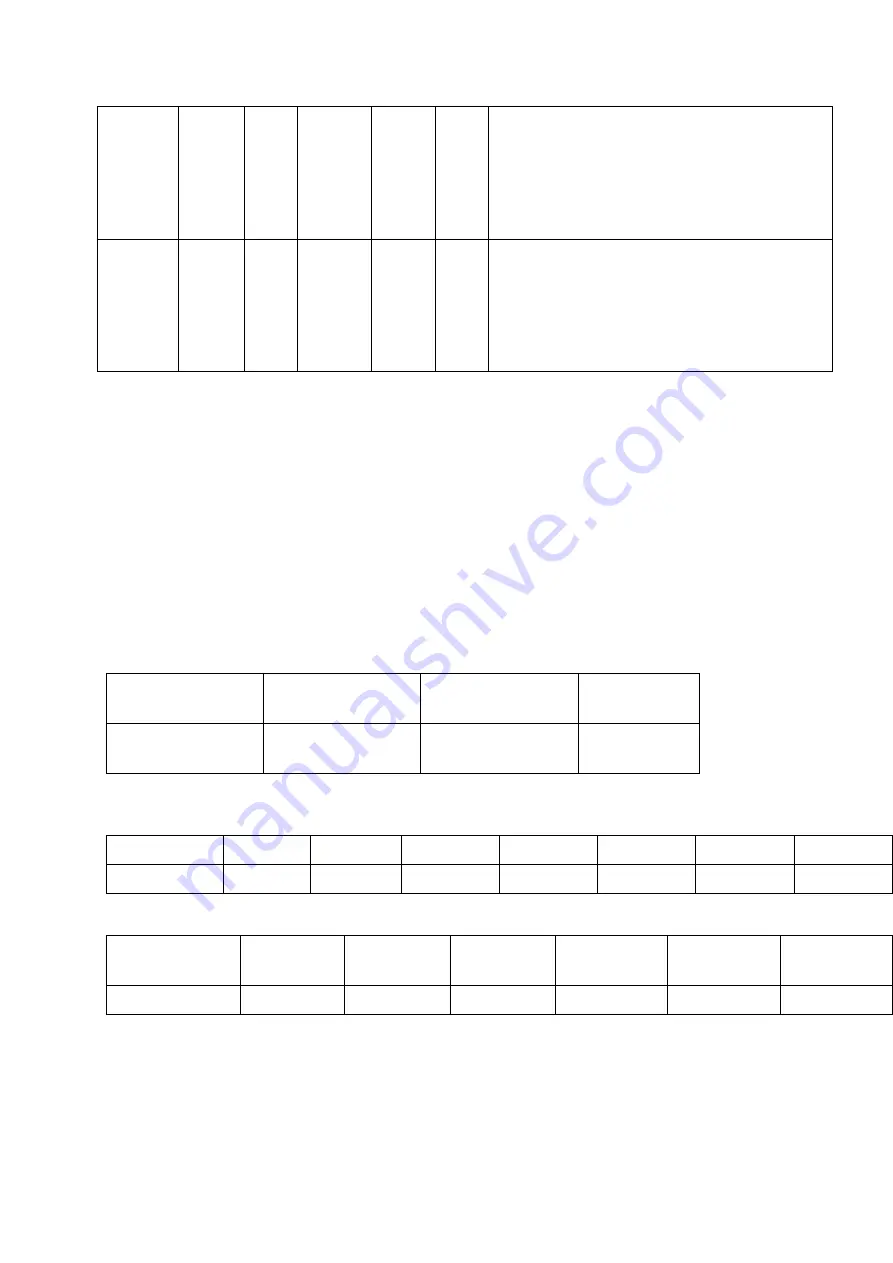

HOW SET CONTROLLER IN TIMED SEQUENCE CONTROL

If the real flow on the dryer is lower than nominal flow, the end user can reduce the

air purge changing parameter P1. Do not change P2 if not agreed with the

manufacturer.

P1

3 default

6 / 9

9 / 18

Real Flow %

100 / 85 %

85 / 70 %

70 / 50

To calculate Real Flow % use the follows instructions:

Correction factors for working pressure

Pressure Bar 4

5

6

7

8

9

10

Factor P

0,63

0,75

0,88

1

1,14

1,25

1,39

Correction factors for inlet temperature

Temperature

°C

25

30

35

40

45

50

Factor T

1

1

1

0,97

0,88

0,73

Real Flow % = Max real Flow / Adjusted Nominal Flow

Adjusted Nominal Flow = Nominal Flow x Factor P x Factor T

Summary of Contents for HGL 120

Page 17: ...B Schemat przep ywu powietrza...

Page 18: ...C Wymiary osuszacza...

Page 20: ...D Schemat elektryczny...

Page 21: ...E Widok rozstrzelony...

Page 23: ...DESICCANT DRYER Instruction and Maintenance Manual...

Page 24: ...HGO 40 160 HGL 40 160...

Page 27: ...B Flow diagram C Dryer dimensions D Wiring diagram E Exploded view F Suggested spares...

Page 41: ...LIST OF ATTACHMENTS...

Page 44: ...A C IN L E T O U T L E T IN L E T E B F G D MODEL 40 80 120 160 INLET OUTLET INLET...

Page 46: ...D WIRING DIAGRAM C CONTROLLER EMV 1 EMV 2 EMV 3 EMV 4 EMV ELECTROMAGNETIC VALVE...