)

Check the condition of the cement floor.

)

Check the torque of the fastening anchor. Also

see the assembly protocol.

)

The condition and function of the load suspension

means are to be checked.

)

Check the torque of the fastening screws.

Torque (Nm) for !haft !cre;!

Fastening class 8.8

0.11*

0.15**

0.20***

M8

20

25

30

M10

40

50

60

M12

69

87

105

M16

170

220

260

M20

340

430

520

M24

590

740

890

Fastening class 10.9

0.11*

0.15**

0.20***

M8

30

37

44

M10

59

73

87

M12

100

125

151

M16

250

315

380

M20

490

615

740

M24

840

1050

1250

*

Slide friction number 0.10 for very good surface,

lubricated

** Slide friction number, 0.15 for good surfaces, lubricated

or dry

*** Slide friction number 0.20 surface black or phosphated,

dry

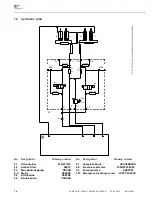

) Check electrical components for function. Re-

place any damaged components.

Optional CE stop switch and signalling unit

Push button, main switch

Electrical cable

During assembly and maintenance always check

the condition of electrical lines. All cables and

lines must be secured so they cannot be crushed,

kinked or contact any moving assembly.

)

Check hydraulic oil.

The oil is used if it has a milky colour or if the hy-

draulic oil smells unpleasantly.

)

Check the hydraulic lines and screws for leaks.

Hose lines are to be replaced:

)

for damage to the outer coating up to the in-

!ert (chafe mark!, cut!, crack!)

)

for brittlene!! of the outer coating (crack for-

mation), deformation of the natural shape in

the depressurized and in pressurized states.

)

if leaking

)

for damage or deformation of the mounting

fi’

-

ture

)

if the mounting

fi’ture

ha! meandered

)

if the lifetime has been exceeded

Repair of the hose line using the implemented

ho!e

”

mounting

fi’ture

i! not permitted!

Extending the replacement intervals given in the

guideline is possible if the inspection for safe-work

condition is done in adjusted, shortened time

frames, if required and by competent personnel.

If ther is an extension of the replacement interval,

no situation may occur which could result in injury

of employees or other personnel.

)

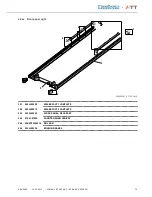

Check the condition and function of all available

safety devices.

)

Check the foot bumper for condition and func-

tion. Exchange if damaged

60

JUMBO LIFT 3200 NT - HYMAX XX 3200 PH

19.05.2015

AD H9402

Summary of Contents for HYMAX XX 3200 PH

Page 3: ...ENGLISH Translation...