18

Recommendations for service

Rinsing and performance

For security reasons, the device must perform when collectors are not exposed to sunlight, where it is

necessary to cover collectors. Especially in areas where there is danger of frost, facility has to be filled

with a mixture of water containing up to 40% of frost protection. To protect the materials from excessive

heat load device is to be filled and placed in service as soon as possible, but not after 4 weeks. If this is not

possible before putting into operation is necessary to replace gaskets to prevent leaks.

Pre-mixed composition frost protection is necessary before filling in device mixed with

water!

Recommended means of frost protection for flat plate collectors: TYFOCOR-L

40% of the means of frost protection (60% / water) - frost point of - 22 ° C / FREEZING POINT: - 26 ° C

50% of the means of frost protection (50% / water) - frost point of - 32 ° C / FREEZING POINT: - 44 ° C

It is possible that filled collectors can no longer be completely removed. For this reason the threat of frost

collectors may also be carried out in order to perform pressure and functional testing only a mixture of

water and frost protection. Alternatively, you can also do a pressure test using compressed air and spray

the leak search jobs.

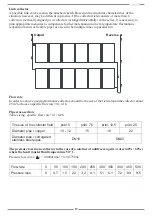

Mounting the sensor

The temperature sensor should be mounted in the outlet collector box located next to the sensor housing.

In order to ensure optimal contact, the gap between the housing and a sensor with adequate heat-

conductive paste. When installing the sensor may be used only material with sufficient resistance to high

temperatures (250 ° C) (body sensor, contact paste, wire, sealants, insulation).

Operating pressure

Max operating pressure is 10 bar.

Ventilation

Equipment must be vented:

-

when it is placed in service (after filling),

-

4 weeks after commissioning,

-

if necessary, for example in case of disturbances.

Danger of scalding hot steam or heat transfer fluid!

The ventilation valve handle only when the heat transfer fluid temperature < 60 °. In the discharge device

may be hot collectors! Cover Collectors and let out device preferably in the morning.

Control of heat transfer fluid

Every two years, it is necessary to check the frost protection and heat transfer medium pH.

-

Frost protection, check with measuring means frost protection and if necessary replace or add the means.

Required value of protection is approx. - 25 ° C to - 30 ° C or by weather conditions.

-

Check the pH with indicator sticks pH (nominal value is approx. PH 7.5):

In case of fall below a threshold pH L 7 replace heat transfer medium.

Maintenance collector

Collector or collector array must be visually inspected every year - if they are not damaged, the seal,

pollution, etc. Other recommendations for operation and maintenance can be found in the general

instructions for commissioning and maintenance / rules from the supplier.

Attention:

Warning: