19

Link collector

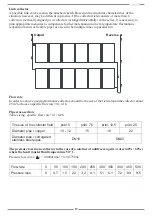

A possible link can be seen in the attached sketch. Based on the structural characteristics of the

situation, however, may be different in practice. If the collector field consists of more than 6

collectors (vertically aligned) or 4 collectors (arranged horizontally) in the series, it is necessary to

plan appropriate measures to compensate for thermal expansion due to temperature fluctuations

(expansion bends or flexible pipe) or a field to be multiple times in parallel run.

Output

Reverse

Flow rate

In order to achieve good performance collector,

should be the size of the field around the collector about

25 m² to choose a specific flow rate 30 l / m² h.

Pipe cross-section

Table sizing, specific flow rate 30 l /

m

2

h

The size of the collector field

Diameter pipe / copper

Diameter pipe / corrugated

stainless steel pipes

pribl. 5

10 - 12

DN16

pribl. 7,5

15

pribl. 12,5

18

DN20

pribl. 25

22

The pressure loss in one collector in the case of a mixture of antifreeze agent / water (40% / 60%)

where the heat transfer fluid temperature 50 ° C.

Pressure loss curve:

p = 0,0000106x² + 0,0137580x

Flow rate

Pressure loss

0

0,7

0

50

1,5

100

150

2,3

3,2

200

250

4,1

5,1

300

350

6,1

7,2

400

450

8,3

9,5

500