4

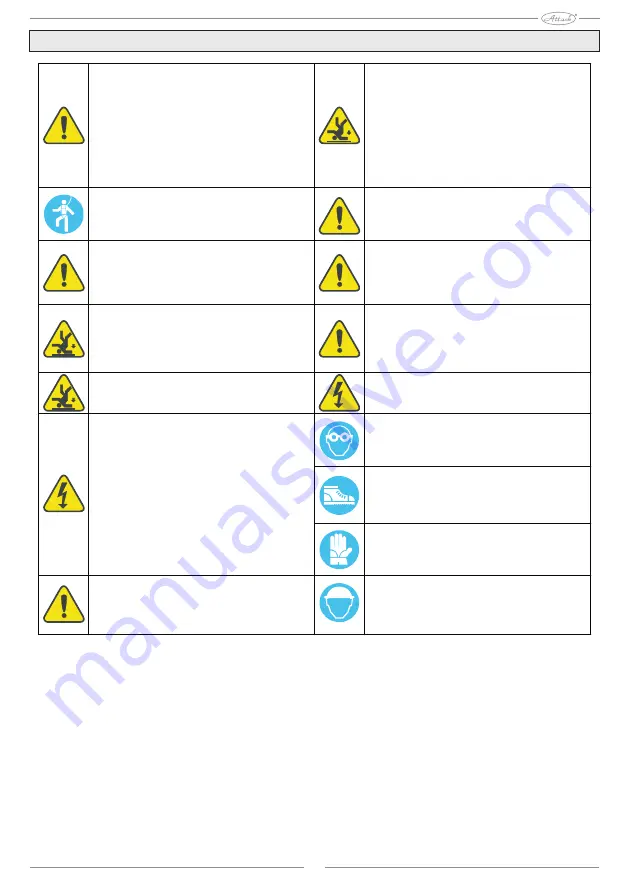

Safety warnings

In the case of mounting on the roof - before the work –

it is essential to install compliant independent

protection against falling or catching device according

to DIN 18338 on roofing work on the roof and sealing

work on roofs and in accordance with DIN 18451 for

work on scaffolding safety net! Regulation on the

protection of workers in construction BGBl 340/1994 §

7-10! It is absolutely necessary to keep other

regulations in the country!

Safety harness must be preferably nailed above the

user. Fix safety harness only to eventually building

components or points that have sufficient capacity!

Only prescribed heat transfer medium!

If there are no safeguards against falling or catching

device-independent entities due to the technical

reasons, it is necessary to use a safety harness!

Do not use damaged ladders, for example cracked

beams with a wooden ladder rungs, bent and broken

metal ladders. Do not repair brittle beams, side walls

and walls of wooden ladders!

Use only safety harnesses, which are identified and

tested by authorized testing laboratory (safety or

webbing, connecting cords / belts, shock absorbers,

shortening ropes).

Place the strap-on ladders safely. Be careful when

attaching the right angle (68 ° - 75 °). Strap ladders

are secured against slipping, overturning, sliding and

running, for example advanced bases, bases ladder

adapted substrate hinges.

If there are no protection devices against falling or

catching independent on people, without the use of

safety harnesses there is danger of falling from great

heights and thus of severe or fatal injuries!

Ladders rest only to the secure anchors. In the field of

transport ensure ladders by closures.

When using ladders, there is danger of falls caused

by slipping, fall or flip over the ladder!

Contact with loose electrical lines can be fatal.

In the case of drilling and handling collectors wear

goggles!

During installation, wear safety boots!

When mounting and handling collectors, wear gloves

providing protection against cuts!

The manufacturer hereby undertakes to take back

products marked with the ecological brand and

materials they contain, to deliver for further

processing. Only prescribed heat transfer medium can

be used!

During installation, wear a helmet!

Near unattached electrical lines, with which contact is

possible, work only if state was secured when they

are not under voltage and this condition is ensured

during the entire period of work, electrically conductive

parts are protected by fencing or covering them, and

there is no reduction of safety distance.

Radius of voltage

1 m ...........................1000 V voltage

2 m ...........................voltage from 1000 to 11000 V

3 m ...........................voltage from 11000 to 22000 V

4 m ...........................voltage from 22000 to 38000 V

> 5 m in the case of unknown voltage