2

WARNING

CARBON MONOXIDE POISONING

Properly seal vent assembly to prevent carbon monoxide from entering

coach.

DO NOT draw combustion air from living area.

DO NOT vent exhaust air into the living area or an enclosed porch.

WARNING

CARBON MONOXIDE POISONING

Furnace must be installed and vented to these instructions.

Improper

installation,

adjustment,

alteration,

service

or

maintenance can cause injury or property damage.

Improper installation location may cause furnace to produce negative

pressure, affecting combustion air or venting of other appliances.

WARNING

CARBON MONOXIDE POISONING

Properly seal door to prevent carbon monoxide from entering

coach.

Properly adjust draft cap to prevent carbon monoxide from

entering coach.

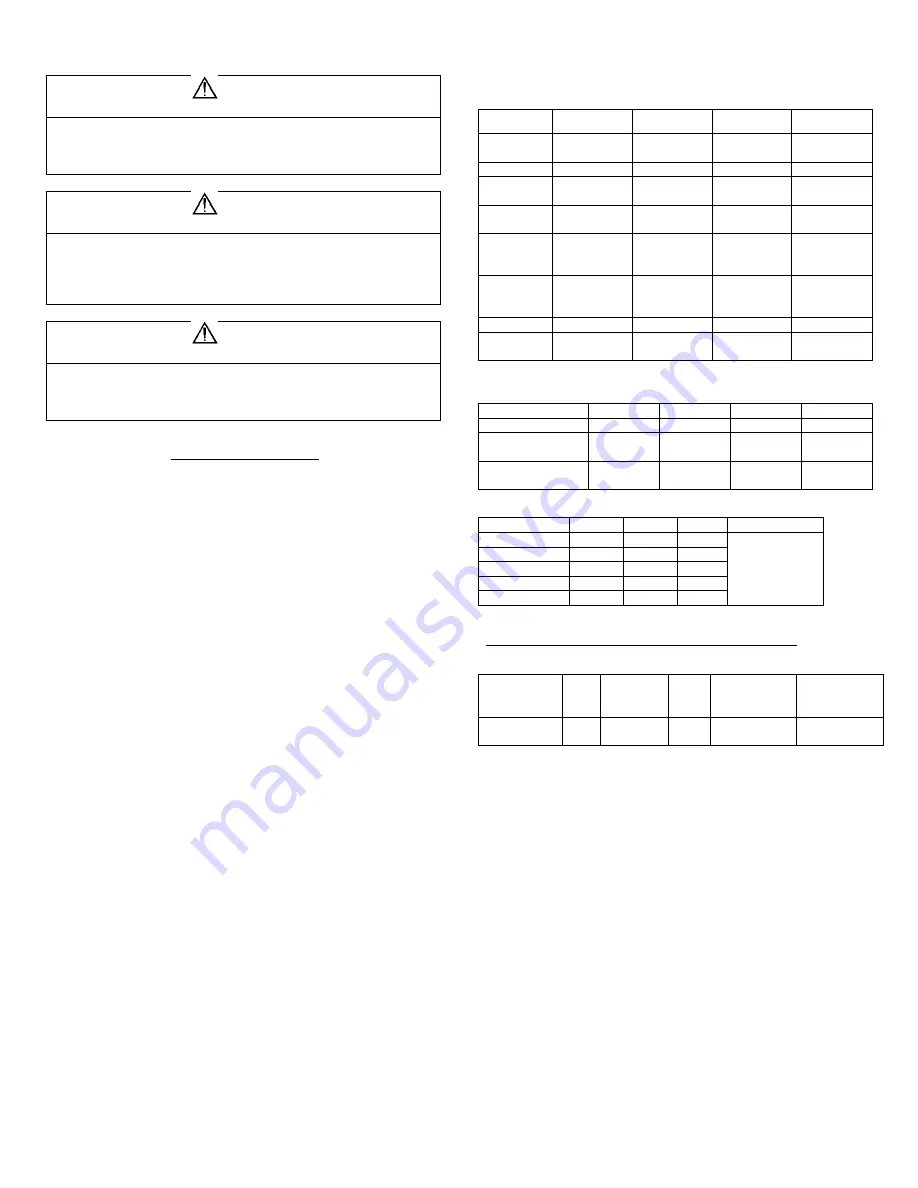

Model Nomenclature

AF

M

D

25

1

1

1

A

Atwood

Furnace

Cabinet

Size

Voltage

Input

Btu/hr

Gas

Type

Gas

Fitting

or Style

Valve

Model

Rev

S=small

D=12

VDC

12K

16K

1=LP

1=Inside

Door

1

Single

A

M=medium

A=120

VAC

20K

25K

2=LP/NAT

2=Outside

LD

2 Stage

L=large

30K

35K

SA=small

low amp

40K

Contents

SPECIFICATIONS

................................................................... 2

MODEL Table 1

............................................................................. 2

DUCTING CONFIGURATION Table 2

........................................... 2

DIMENSION Table 3

..................................................................... 2

MINIMUM CLEARANCE TO COMBUSTIBLES: Table 4

.............. 2

INSTALLATION AND SAFETY CODES

.................................. 3

GENERAL FURNACE LOCATION AND INSTALLATIONS

... 3

FURNACE INSTALLATION

..................................................... 3

WALL CUTOUTS Table 5

............................................................. 3

SMALL VENT INSTALLATION

................................................................ 3

STANDARD DOOR INSTALLATION

....................................................... 4

INTERIOR GRILL INSTALLATION

.......................................................... 4

FLEXIBLE DUCTING SYSTEMS

.............................................................. 5

PROPANE GAS CONNECTION

.............................................. 5

ELECTRICAL CONNECTIONS

............................................... 5

THERMOSTAT INSTALLATION

............................................. 6

OPERATING INSTRUCTIONS

................................................ 6

WIRING AND LADDER DIAGRAM .......................................... 7

PART DRAWINGS & PART LISTS

......................................... 8

SPECIFICATIONS

MODEL Table 1

Models #

AFSD12111

AFSD12121

AFSD16111

AFSD16121

AFSD20111

AFSd20121

AFSAD12111

AFSAD12121

Type of

Gas

LP/Propane

LP/Propane

LP/Propane

LP/Propane

BTU Input

12,000

16,000

18,000

12,000

BTU

Output

9,120

12,160

13,680

9,120

Duct Static

Pressure

0.1

0”WC

0

.10”WC

0

.10”WC

Non ducted

12 Volt

Amperage

(AMPS)

3.4

3.4

4.8

2.4

Power

Supply

(Volt DC)

12

12

12

12

Watts

41

41

56

34

Minimum

Return Air

35 in

2

35 in

2

35 in

2

35 in

2

(WC = WATER COLUMN)

DUCTING CONFIGURATION Table 2

Models

AFSD12

AFSD16

AFSD20

AFSAD12

Side Ducting

2 Ducts

2 Ducts

2 Ducts

N/A

Front with Side

Ducting

1 or 2

Ducts

1 or 2

Ducts

1 or 2

Ducts

N/A

Front Only no

Side Ducts

Front

Front

Front

Front

DIMENSION Table 3

Approx. Dim.

Height

Width

Depth

Weight

Casing

7”

12”

20”

Furnace 21 lbs

Boxed 24 lbs

Vent (LD)

4-5/8

”

6-5/16

”

1-1/6

”

Door

9-3/4

”

14-3/4

”

1/2”

Interior Grill

12-

1/2”

8-

1/2”

1/2

”

Trim Ring

10-1/8

” 14-1/8”

1/8

”

MINIMUM CLEARANCE TO COMBUSTIBLES: Table 4

Floorboards, walls & similar combustible building materials

must be provided the full length and width of the unit.

clearances

Top

Sides

Rear

Bottom (to

screw

heads)

Blower (side

opening)

Vertical /

Horizontal

1/2”

1/2”

1/2

”

0”

36 sq. in.

Spacing of 1

/4” to ducting within 3 feet of furnace must be provided

unless UL listed wire bound vinyl ducts are used. All ducting material

must be rated for continuous use at minimum of 200°F.

Clearances are specifically for plywood or similar building materials

surrounding the furnace (i.e. Furnace should not be located under

furniture or in a closet space where clothing or other material could be

located).

Furnace efficiency rating is a thermal rating determined under

continuous operating conditions, independent of any installation.

Efficiency rate is given at 76% minimum; actual efficiency rating may

be higher.

Return air is supplied through openings or around the furnace. All

return air passages must be kept clear for furnace to function properly.

Refer to Minimum clearance to floorboards, walls & similar combustible

building material in Table 4.

The total unobstructed return air opening size must not be less than

specified in specification Table 1. Failure to meet minimum return air

requirements nullifies furnace warranty.

To install without adding the additional 16 sq. in. cutout on the blower

side supply the right side of unit (blower side) with 2” clearance full

length of the unit.

Summary of Contents for AFSAD12111

Page 7: ...7 WIRING AND LADDER DIAGRAM ...

Page 8: ...8 PART DRAWINGS PART LISTS ...

Page 9: ...9 ...

Page 10: ...10 ...