1

THIS INSTRUCTION MANUAL IS FOR USE BY AN AUTHORIZED SERVICE

TECHNICIAN TO INSTALL AN ATWOOD

- hydro flame

TM

FURNACE

.

TO THE INSTALLER

:

THESE INSTRUCTIONS MUST BE SUPPLIED WITH THE FURNACE TO THE CON

-

SUMER

.

PLEASE RETAIN THESE INSTRUCTIONS FOR FURTHER REFERENCE

.

This furnace design has been certified for installation in recre-

ation vehicles as a MSP Category III furnace. Follow this installa-

tion instruction to insure safe operation of the furnace. Failure to

install furnace according to this installation instruction nullifies

the furnace warranty.

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards.

Obey all safety messages following these symbols.

WARNING

CAUTION

avoid possible

avoid possible

injury or death

injury and/or property damage

INDEX

FURNACE SPECIFICATIONS

..............................................................1

DIMENSIONS

..................................................................1

WEIGHT

........................................................................1

MINIMUM CLEARANCE TO FLOORBOARDS

,

WALLS

,

&

SIMILAR COMBUSTIBLE BUILDING MATERIALS

..................................

2

SAFETY INFORMATION

..................................................................

1-2

FURNACE INSTALLATION

..................................................................

2

WALL CUTOUT

........................................................................

2

-

3

DUCTING

..................................................................................

3

Flexible Ducting

......................................................................

3

Hard Ducting

........................................................................

3

OPTIONAL INSTALLATION

-

BOTTOM DISCHARGE KIT

..................................

3

GAS CONNECTION

........................................................................

3

ELECTRICAL CONNECTIONS

..........................................................

3-4

Conductor Sizing Table

............................................................

3

12 volt DC Models

................................................................

3-4

120 volt AC Models

................................................................

4

Thermostat

..........................................................................

4

DOOR INSTALLATION

....................................................................

4

RAIN SHIELD INSTALLATION

............................................................

4

DRAFT CAP ASSEMBLY

..................................................................

4

CONVERTIBLE GAS CONTROL

........................................................

4-5

Valve Conversion

....................................................................

4

Orifice Replacement

................................................................

5

SYSTEM CHECK TESTS

....................................................................

5

PROPANE GAS PRESSURE

..............................................................

5

STATIC PRESSURE

........................................................................

5

AC

&

DC WIRING DIAGRAMS

............................................................

5

ILLUSTRATIONS

............................................................................

6

REPLACEMENT PARTS LIST

&

DRAWING

..............................................

7

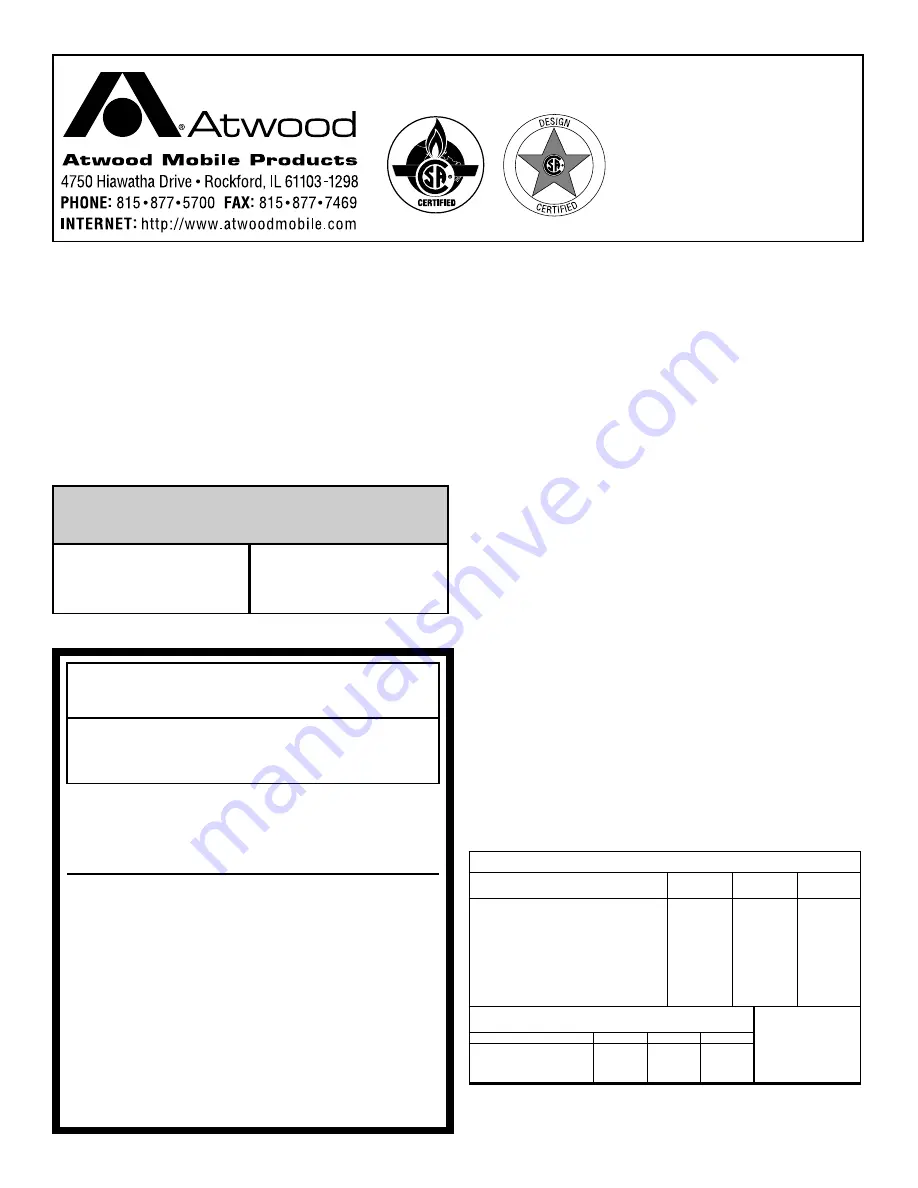

SPECIFICATIONS

*

(W.C. = Water Column)

MODEL

#

8935

8940

8935

8940

DCLP

-

III

DCLP

-

III

ACLC

-

III

ACLC

-

III

BTU Input

35,000

40,000

35,000

40,000

Output BTU/HR

27,300

31,200

27,300

31,200

Type Gas

LP

LP

LP/NAT

LP/NAT

Duct Static Pressure -

.10˝ W.C.*

.10˝ W.C.

.10˝ W.C.

.10˝ W.C.

Power Supply (

VOLTS

)

12-DC

12-DC

120-AC

120-AC

Watts

132

132

360

360

Amperage

11

11

3

3

MINIMUM RETURN AIR

80 in

2

80 in

2

80 in

2

80 in

2

DIMENSIONS

WEIGHT

ALL MODELS WITH DOOR

WIDTH

HEIGHT

DEPTH

Casing

16-1/2˝

9-1/8˝

23-1/2˝

FURNACE

38 lbs.

Door

19-1/4˝

9-1/4˝

1/4˝

SHIPPING

45 lbs.

Recess Bezel

20-9/16˝

11-1/2˝

ENGLISH, FRANCAIS

(et Canada)

•Installation

Effective 4/1/03

LITERATURE NUMBER

MPD 34473

hydro flame

TM

8900-III Series Furnace

MODELS

8935, 8940

Technical Installation Manual

WARNING

FIRE OR EXPLOSION

• If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

FOR YOUR SAFETY

WARNING

FIRE OR EXPLOSION

WHAT TO DO

IF YOU SMELL GAS

• Evacuate

ALL

persons from vehicle.

• Shut off gas supply at gas container or source.

•

DO NOT

touch any electrical switch, or use any phone or

radio in vehicle.

•

DO NOT

start vehicle’s engine or electric generator.

• Contact nearest gas supplier or qualified Service Technician

for repairs.

• If you cannot reach a gas supplier or qualified Service

Technician, contact the nearest fire department.

•

DO NOT

turn on gas supply until gas leak(s) has been repaired.

Installation and service must be performed by a qualified

Service Technician, Service Center or gas supplier.